———–

Note: This is the first part of a 2-part story on the initial article written by Chuck Manning on how to build your own sports car. Click here to review both parts of this story.

———–

Hi Gang…

Allow me to welcome back Joel Driskill to the land of Forgotten Fiberglass. If you remember in an earlier story on Chuck Manning, Joel is in the process of building his own “Manning Special” following many of the guidelines but forth by Chuck back in the ‘50s.

The story of the Manning Special was inspirational to many of the folks back then. Not only did Chuck run his car to great success in many a race, but he sold plans of how to build your own car and chassis too. Some of the best known specials used the Manning chassis blueprints as the basis for their car – one of the best known being the Guy Mabee Victress Special which became the “World’s Fastest Sports Car” at 202+ mph at Bonneville in August, ’53.

Joel and I are teaming up to present many of the “Chuck Manning” articles in their original form – along with Joel’s own thoughts – and comments from each of you.

And with that, let’s turn it over to Joel.

Go get ‘em Joel!

Joel Driskill: Forgotten Fiberglass Chuck Manning Correspondent

Introducing Today’s Article

Today’s story is special in that it introduced Manning and his home-built special to the general public. This introduction was broken up into 2 installations and this is the first of the two. I believe this article to be the first of many that would be written by Chuck or about Chuck

In this article he lays out the basis of what a sports car should be and generally how it should be set up. He also shows the results of some simple algebraic equations proving the best setup for a sports car, the equations would be showed in the second installation of this article.

That is not to be confused with how hard the derivation of these algebraic equations was, but how easy it is to use them to get to a logical answer. This proved how smart Manning was and what an innovator he was. It is stated at the beginning of the article by John Bond the Tech Editor that the publishing of these calculations was a first, and the fact the Chuck derived them is fantastic.

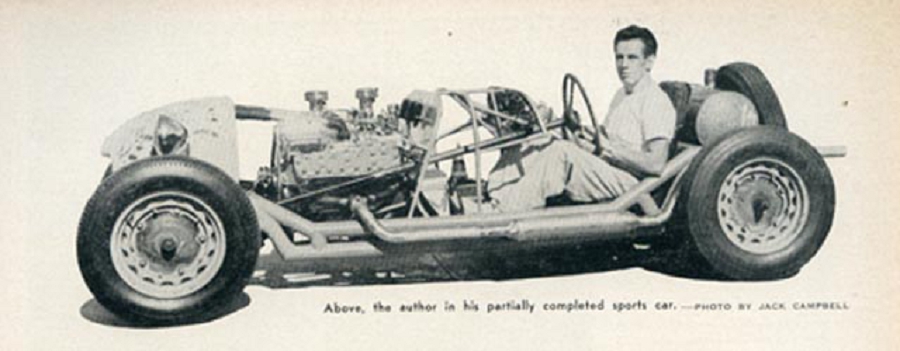

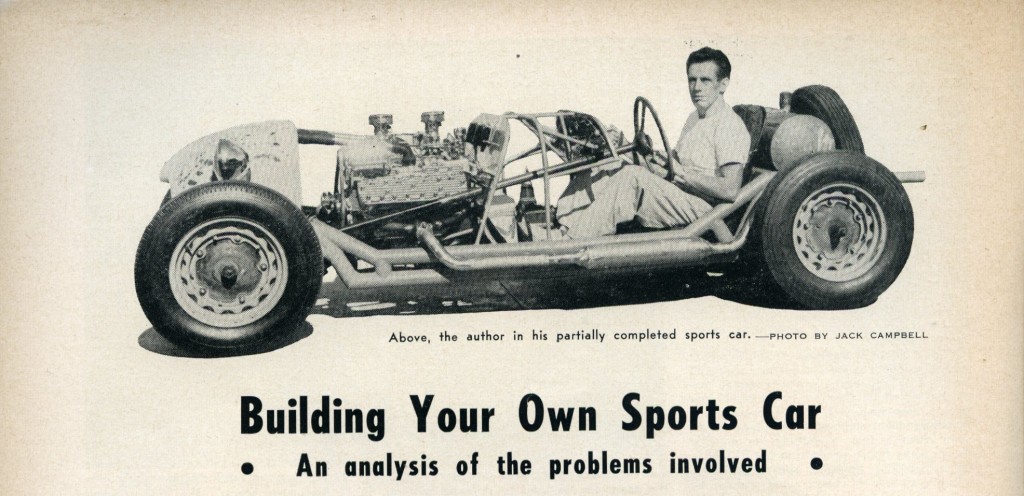

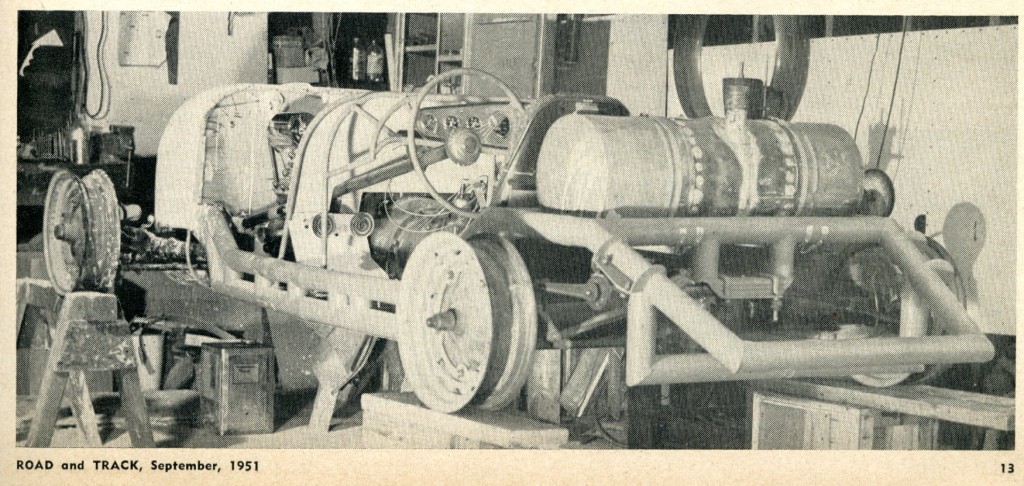

It also shows some insight of some of what it takes to build a successful race car and what one would have to consider before the building of one. The pictures in this article are great in that they show the car in its early stages in the build.

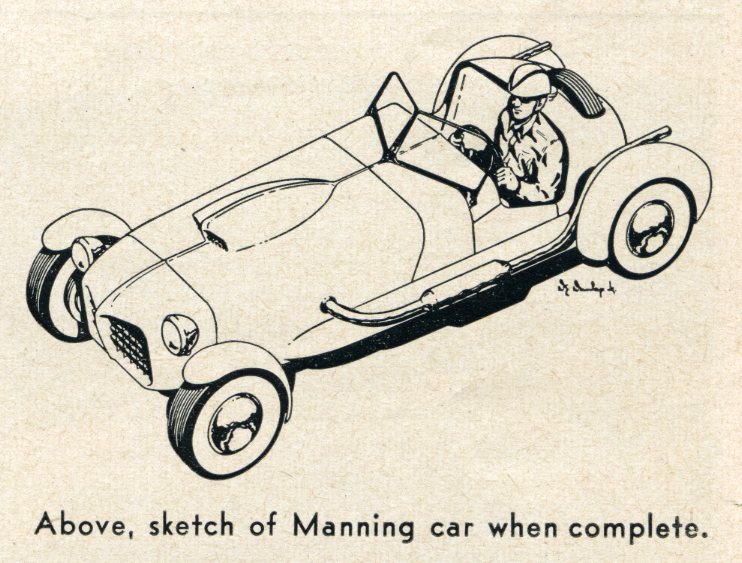

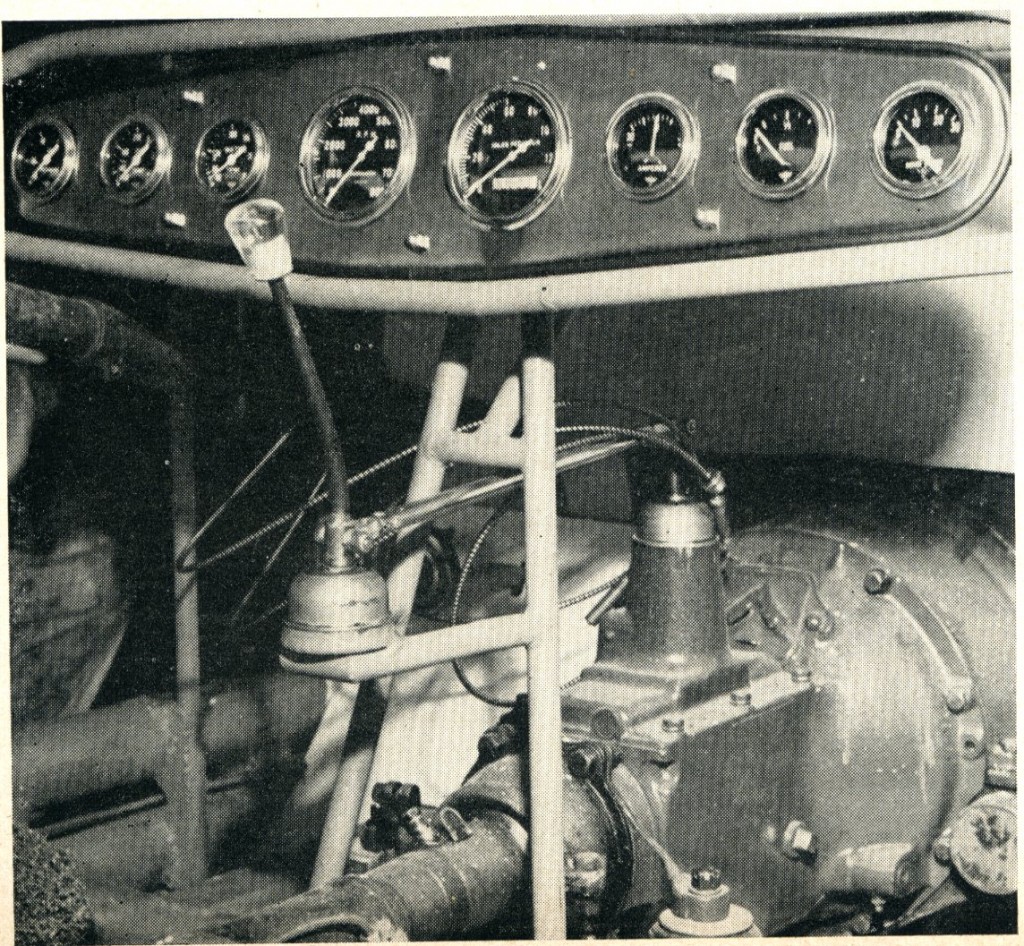

In one of pictures the nose of the car is still just the plug that was built on the chassis. The other picture shows the unpainted/unfinished nose. They also show great details of the parts of the build including the war surplus propeller de-icer tank. A future state sketch of the Manning Special is also displayed in the article, showing white wall tires, molded hood scoop and a V style wind shield.

The hot rod minded Mercury builder comes through in that sketch. Enjoy the first installment of “Building Your Own Sports Car” and hopefully it gets the gears turning and motivates you to do exactly that!

Building Your Own Sports Car: Part 1 – Road & Track, September 1951

An Analysis of the Problems Involved

by Charles G. Manning

Road & Track, September 1951

Editor’s Note:

The author, a stress analyst for Douglas Aircraft, has made a hobby of the mathematical analysis of sports car cornering characteristics and is putting his theories to test by actually building a car. In this article, Mr. Manning breaks new ground insofar as published material is concerned by analyzing various types of suspensions and their net effect on cornering ability.

By taking a “standard” sports car and putting it into a “standard” corner, he computes the results of various suspension changes in such a manner that comparisons of changes can be made. Since the inside rear wheel does all the driving in a corner, and since this wheel inevitably tends to lift off the road surface, the problem simplifies to one of reducing this lifting tendency so that more horsepower or tractive effort can be transmitted.

The conclusion shows that by designing the front end to take more of the overturning moment, the inside rear wheel can be made to transmit more power. The author cites the Allard J.2 as representing close to the ultimate in cornering ability due to high roll center both front and rear. The appendix gives the derivation and solution of the mathematical approach, and many minor factors have been omitted in order to simplify the process. However, these “minor factors” were all carefully considered and proved “minor” before the simplification was used.

–Tech. Ed.

With the large variety of truly excellent sports cars available, the question immediately arises: Why build one? There are several answers to this. Money, for one thing because sports cars can be expensive. Then, too there are those who, for some unknown reason, would rather build something of their own than buy it. So if you are somewhat of a hobbyist, and if time is no object, then pull up a chair and let’s see what we can dream up.

First of all, we must remember one thing. All designs amount to compromise. The car you build can have just the characteristics you want it to have. Details which you may consider unimportant (such as soft ride) may be somewhat neglected, while features you may thing important (such as cornering) may be emphasized.

In this discussion, we are chiefly interested in handling qualities, which can be changed (and improved) for a total cost to you of $500 to $1000, if you discount your time.

We must remember that in a sports car, we have an engine, two people and four wheels to consider. Tow of these four wheels must steer, and two must apply power. This suggests an infinite variety of combinations, some of which we may discard at the outset as being simply not feasible.

The Sports car must steer from the front, if we are to avoid trouble. No rear steering setup has ever been successful-even theoretically. Also, the car we are considering shall employ a full differential, since a locked axle results in prohibitive tire wear during road racing. While a limited-slip differential solves many of the problems we shall face, the cost is too high and we want to keep our financial outlay down.

This leave us four possible chassis layouts or arrangements. Let’s look at their several advantages and disadvantages.

Basic Arrangements

TYPE I

Forward engine, rear-wheel drive

Advantages

a. rear seating position (better “feel”)

b. even tire wear (steering front, power rear)

c. inexpensive to build

Disadvantages

a. difficulty of attaining 60% of weight on driving wheels

b. weight of drive shaft

c. suspension problems

TYPE II

Rear engine, rear-wheel drive

Advantages

a. easy weight distribution control

b. no drive shaft

c. even tire wear

Disadvantages

a. high driver skill required

b. cooling system problems

c. suspension problems

d. complicated gear-shift linkage

TYPE III

Forward engine, front-wheel drive

Advantages

a. less driver skill required

b. no suspension problems

c. no weight control problems (70% forward)

d. no drive shaft

Disadvantages

a. very uneven tire wear (power & steering on front wheels)

b. high cost of front wheel drive mechanism

c. steering lock reduced

d. complicated gearshift linkage

TYPE IV

Rear engine front-wheel drive

Advantages

none

Arrangement Choice:

Were we to list all the above items in order of importance-the degree of driver skill required would unquestionably be first. The rear engine car must always have either a driver position too far forward to too large a percent of the weight on the rear wheels. Either-for the amateur driver-would be equally disastrous. With the forward seating position, the driver has little forewarning when the tail-end start to slide and therefore cannot “correct” quickly enough.

Cornering vigorously becomes a series of erratic broadslides interspersed with period when all four wheels are tracking. All too often the final result is “losing it completely” or ending up in the hay bales. When 60% or more of the weight is on the rear wheels, very violent “tail chasing” results. If, for any reason, the tail of the car moves out to a broadsliding angle of greater than 10 or 15 degrees – you have “lost it,” and any amount of throttle, brakes or steering won’t help. In short, few amateur drivers are able to corner successfully in a rear-engined car.

Suspension:

The next most important item is suspension. the requirements of suspension in order of their importance are: correct toll center height, front and rear; correct steering geometry during both bounce and turn; and minimum unsprung weight.

The roll center of a suspension is defined as the point about which the sprung weight rolls when the car is accelerating sideways (as in a turn). The roll axis is a line joining the roll centers of the front and rear suspension and is the axis about which the body rolls. Correct steering geometry during a turn specifies all four wheels tracking arcs about a common center.

Correct steering geometry during bounce specifies no change in caster, camber, toe-in, tread, wheelbase, or roll center. The ratio of sprung to unsprung weight for a rally smooth ride will approach 20-1. For our design, any ratio of less than 4-1 should be considered unacceptable as even moderately rough roads will set up axle tramp in spite of adequate damping from the shocks.

To illustrate the importance of the position of the roll axis, let us ran thru a few examples based on the Jaguar XK-120 weight, center of gravity location and other factors.

- For comparison, let us first use accepted American passenger car roll stiffness, front and rear, with Jaguar suspension geometry.

- Car No. 2 will be the Jaguar XK-120 and we are indebted to Automobile Engineer for the spring rates and geometry.

- Replacing the XK parallel, a frame front suspension with a half-wing front axle (or a solid F.A.) and removing the roll bar gives us our third example.

- Adding the XK roll bar to example #3 gives us our fourth case.

- Adding a DeDion rear end to example #4 will be the fifth type.

The following table shows the relative ability of each car to use its available power in a turn and during straight-line acceleration. The first column identifies the type as itemized above. The second column shows the distance gained on the first car in the 90deg right turn described in the appendix.

The third column shows horsepower required to accomplish this gain. The fourth column shows initial thrust possible for a standing-start straight-line acceleration.

Car Distance gained HP required Initial thrust straight-

Over Car #1 line acceleration-lbs

1 0 33.5 1830

2 12.2 49.5 1712

3 13.6 51.2 1625

4 15.3 53.6 1712

5 31.8 75.0 2030

Inspection of the appendices* will show that, in a sense, the requirements of a suspension for cornering under power and for maximum straight-line acceleration are mutually contradictory. That is, for cornering the suspension should be very stiff in roll at the front. Best straight-line acceleration is accomplished, however, by having all the roll stiffness as the rear.

Further inspection of the appendix, however, shows that during cornering the couple of either front or rear suspension is made up of two separate parts . . . that part which is proportional to C.G. height above the roll axis and the roll stiffness of the springing, and that part which is due to the side load on the tires multiplied by the distance from the ground to the roll center of the suspension.

Also, that during straight-line acceleration the load variation on the tires is a function only of the roll stiffness front and rear. Therefore, to have most of the total over-turning couple carried by the font suspension while in a turn, and also to have most of the engine torque cancelled by the rear suspension during straight-line acceleration, we must make the term Ff Hr (side force rear x roll center height rear) as small as practical.

As Ff and Fr are determined by the weight distributed front and rear and must always be very nearly equal (nearly equal weight on front and rear wheels), it become evident that the car whose roll axis more nearly approaches an upward slope from rear to front (higher in the front that in the rear) has made the best use of the suspension n building a competition machine.

Probably the foremost question in the reader’s mind at this stage is, “What good is ability to apply power in a turn if the solid front axle refused to stick to the road?” First of all, the half swing front axle, which has an even higher roll center than the solid axle, need make no apologies for its ability to keep wheel to ground in a rough corner and is, in fact, considerably better from this standpoint than other types (Ref. letter to “Sports Car” magazine from Allard Motor Car Co. as reported in Aug. Road and Track).

Second- if you cannot have a half swing, you must decide how rough the corners you expect to run around will be. You may then decide that, after all, 95% of the corners in all road races are just about dead smooth and the ones that are not may be taken slower and the solid axle front suspension still comes out with the best lap time.

It should be noted here that if a limited-slip differential (for cornering) were mounted in a sprung center-section type rear suspension 9for straight-line acceleration), all of the foregoing would disintegrate into a discussion of relative tire wear rates, and no difference in performance could be shown.

Therefore, if you must have an independent front suspension (not half swing), your design should include a full independent rear suspension of the same type or a DeDion rear suspension with a limited-slip differential, if you intend to corner and accelerate against cars having solid (or half swing) axles front and rear, but with no limited-slip differential.

Note that the suspension of the J.2 Allard, with its half swing front suspension and DeDion rear, seems to be just about optimum.

Springs and Shocks:

While talking of suspension, we should also decide on the type and spring rate og the springing and kind of damping.

First we should not that the mechanism used to give the desired spring rate matters little. There is no theoretical advantage, one to the other, of leaf springs, coil springs, torsion bars, air cylinders, or the like.

There are, however, some practical advantages and disadvantages of each.

For the very smoothest type of ride our springing must have a very minimum of hysteresis (or friction) loss and, from this standpoint, either the coil and torsion bar spring, combined with a velocity type hydraulic shock, is best. However, for a car that will be driven over rough roads at high speeds, in addition to velocity damping, we must also have a dry friction breakaway type damping.

The leaf spring comes with this feature built in. Therefore, if you must have a torsion sprint, you must have twice as many shocks . . . one friction type and one hydraulic type for each wheel. The absolute value of the sprint rate used is not at all critical . A soft spring requires a larger shock absorber than a stiff spring.

If you spring rate comes out such that increasing the weight on one wheel by 50% gives ya one to two inch deflection- you are close enough,. Or Ss=125 to 250#/in. per wheel.

(Continued next month)

*Appendix will appear at conclusion of article next month.

Summary:

Chuck Manning wrote one detailed article! But if you want to know how it was expertly done “back in the day” – this is a great place to start.

Thanks again for Joel Driskill’s willingness to help place this article here on Forgotten Fiberglass for everyone’s review, and be sure to check on Joel’s website and watch the progress on Joel building his own “Manning Special.”

Click here to visit Joel’s website on building his own “Manning Special”

Joel and I hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————-

Click on the Images Below to View Larger Pictures

——————————————————————-

This question must have been answered somewhere but I can’t seem to find it. The question is are plans for the Manning Special available? If they are where do I go to order them. Really nice site. Thank you.

Hi Joel,

Great job! Love to read what they were thinking when they built their cars. A question: Did Manning sell his car to Sparks and Bonney, or did they build one of their own? What happened to the Manning car?

Thanks,

Harold Pace

Sparks and Bonney through Jaques Bellesiles had the Sparks and Bonney Special Built. Manning did not sell his car to them. Dave Margolian welded that car together for sparks and Bonney/ Jaques. Dave build his own and tried to set up shop selling Manning specials (more stories on that to come). Dave Margolian’s personal Manning Special still exists but the others do not as far as I can tell, only frames from the plan sets exist (The Schagticoke special is something a little different in that it originally did’t look exactly like the Manning car but it does now ). I think Manning’s car was scrapped for its parts and the rest thrown away but I haven’t confirmed that yet. I have heard the Sparks and Bonney Special (a.k.a. Bellesiles special, the solution, Dolden special, blue monster) was sold in the late 50’s but there is no word on what happened to it afterwords. More to come on all of these cars.

Joel

Chuck Manning was an engineer and it shows. The shifter is simple and a basic design. There were few remote shift towers back then – Hurst was years away.

The use of straight solid Ford axels made for far better handling than the split Allard type. Even Frank Kurtis had little use for the Allard axel style and said so when designing his sports car line. The first Allards were for off-road [Trials type] racing.

For years hot rodders liked the handleing of straight axels. Some of my older friends said they were even better if the wish-bone was not split. Briggs Cunningham came to the same rational when building his C6R. After several years running at LeMans he felt a straight axel would work better.

Form follows Function !!!