Hi Gang…

I have the honor of introducing you to another new contributor here on Forgotten Fiberglass: Joel Driskill.

Recently, Joel and I crossed paths on our mutual interest in the sports car built by Chuck Manning in the early ‘50s. And part of the reasons we crossed paths is that he is in the process of both documenting the history of Chuck Manning – and building his own “Chuck Manning Special” following the guidelines Chuck put forth in magazine articles and plans from back in the day.

So why is the “Special” built by Chuck Manning so “special” to us here at Forgotten Fiberglass?

Well…if you were a strapping young man back then, you could build your own fiberglass sports car special – right? We’ve shown how it was done and we continue to share this information too. In this vein, you could purchase a beautifully designed body like a Glasspar, Woodill Wildfire, Victress, Allied, Meteor, or other…and away you would go. You could even take the next step and design your own body for a “one-off” car – like Richard Bosley did.

But that wasn’t your only choice.

You could… build a car based on an expertly designed set of plans.

Plan-Set Cars

There were several “plan-set” cars available in the ’50s. Mechanics Illustrated had one (Bob Frumkin…get ready to help write a story about your car…), and other magazines and entrepreneurs offered them for sale too – at the back of magazines. But one of the most talked about “plan-based” cars was the one designed, built, and raced by Chuck Manning.

So….if you wanted to build your own car in the ‘50s – it might be in fiberglass. Or….it might be by a set of plans where everything including the body was something you hand-crafted. That’s the legacy of a plan-set car, and the most famous one with racing history was built and promoted by Chuck Manning.

I’ve asked Joel to take a lead on the “round-up” and writing concerning the Chuck Manning car. He’s a natural here, since he is building his own, so let me turn over the reins to our newest member of the Forgotten Fiberglass Family – Joel Driskill.

Joel Driskill: Forgotten Fiberglass Chuck Manning Correspondent

Introducing Today’s Article

Today’s story is about Chuck Manning and his Manning Special a.k.a. Mercury Special a.k.a. Meteor Special.

As some of you may know Chuck Manning was an aerospace engineer that worked primarily at Douglas Aircraft but he also worked for the likes of North American and Areojet among others. Chuck Manning made it a hobby of his to use his engineering knowledge and apply it to racing cars.

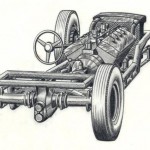

In fact he used this knowledge to design a frame/chassis set up that not only was light but very rigid (12600 in-lbs/deg) and tipping the scales at only 85lbs. Not bad for a ladder type frame, the Kellison frame in a recent story was as stiff but weighed 200lbs. He did more than design this frame – he built the car and went on to win races with it.

He wrote many articles in Road and Track and other magazines about how to build your own race car but only left the readers wanting more. Many people asked for plans and he supplied them for $2 a pop. I’ve learned from interviewing Chuck’s friends that enough people sent $2 to him in the mail that the authorities questioned if he was running a scam.

Instead of a scam, he was arming the “special” builder with the framework to compete against the big boys in racing at a low cost. Although uncommon, there are some examples of the use of Manning’s design under road racing/fiberglass specials.

Today’s story isn’t Chuck’s first article that he wrote but it is significant because it describes his build process and his ideas up to that point. The story calls out what parts he used to make up the special such as ‘38 axles, ‘39 steering column and a de-icer tank for the gas tank. His plans as sold, however, say that he used a ’38 Ford steering. I think it is also important to note that he built the frame literally on the floor of his garage and then he says keep it to within 1/16th of an inch (that is hard to do).

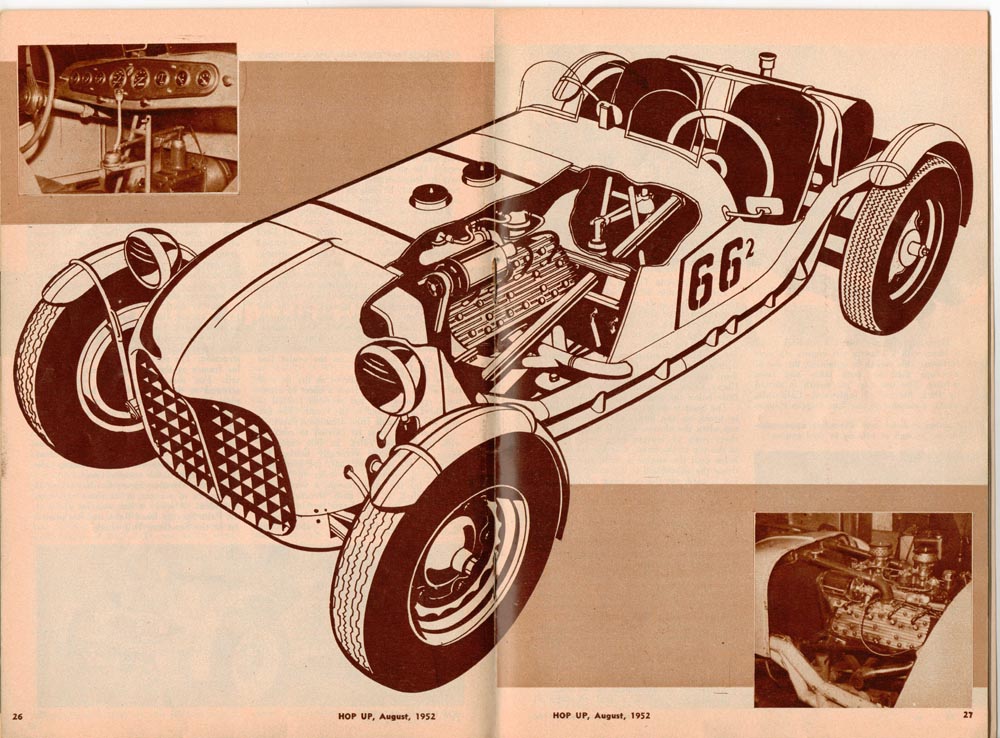

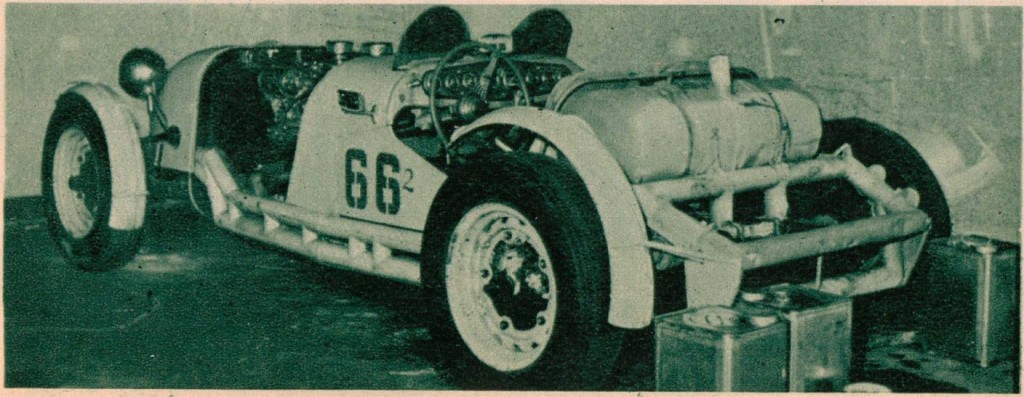

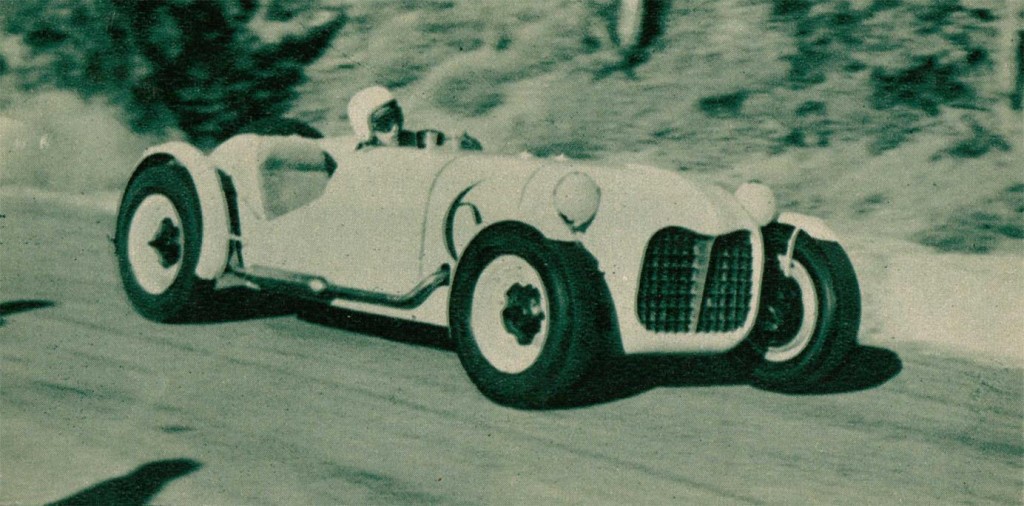

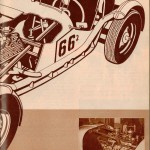

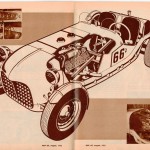

I personally like that the mounting of the spare tire at the rear of the car is considered a roll bar. I wonder if that would pass today’s tech inspection? It may be worth noting that the picture at the top left is a later configuration than that of the picture of the lower right. The way that this is identified as an earlier construction is that the frame rails are not “boxed” in. He later welded shear webs on the frame openings to close them in much like the frame of an aircraft, chord-web-chord.

Very aerospace engineer of him, so was the floor having hat section channels riveted to a flat sheet, a lot like the skin and stringers of an airplane. He also states at the end that he wanted to make a “full body” for the car. A drawing of that is in the HONK article that will be shared in a later story here at Forgotten Fiberglass. He never did complete the “full body,” but he did some fiberglass work on the later stages of the car’s racing life that eliminated the cycle fenders at the front and rear of the car.

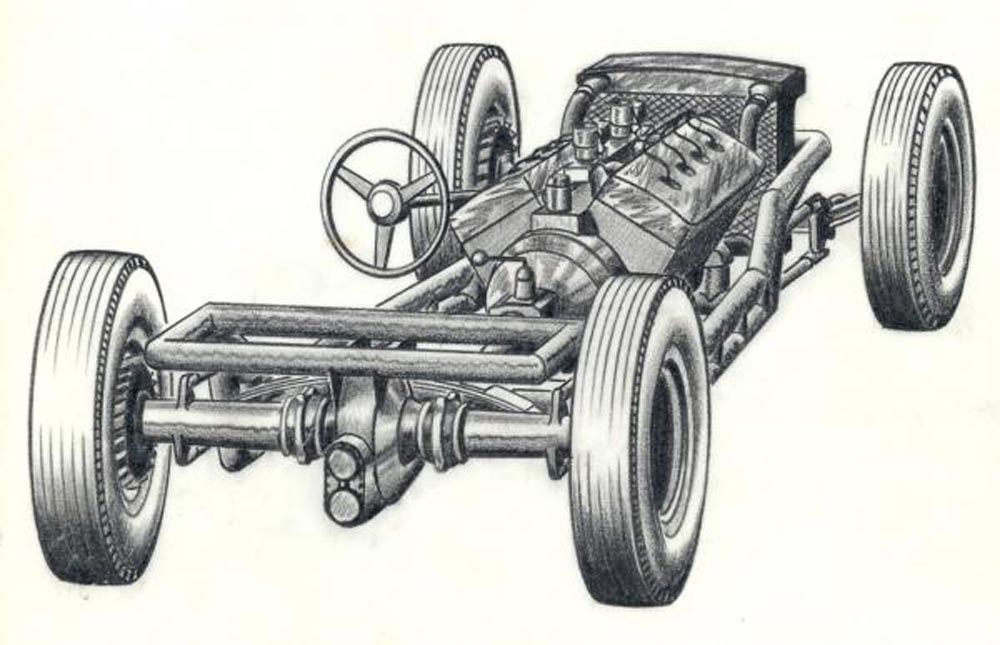

The swing axles were also never completed as far as I know but they were drawn up, the drawing below from his personal collection that depicts his idea of what the swing axles would look like. Without further adieu, from the August 1952 Hop Up Magazine, Chuck Manning himself.

Manning Sports Car: Hop-Up Magazine, August 1952

By Charles Manning

Construction of a high performance sport car brings into consideration important size and weight factors. Both minimum size and minimum weight are necessary in order to compete in this specialized field, and it all seems to start with the frame. Careful searching uncovered no production frame of the proper size that had sufficient stiffness, or construction that was light enough.

With this in mind it was necessary to design and build a frame for the job. After a suitable design had been achieved, it was laid out full size on the garage floor and scribed on the cement. Low carbon steel tubing of 2 3/4″ O.D. was to be used. Sections were cut to proper length and laid in positions on the floor.

The aft cross members were welded into place between the two side rails. Because the front was to be narrower than the rear, the side rails were cut part way through on the inside, at the proper spot. The rails were then brought closer together at the front and the front cross member installed.

Frame alignment must be held to within 1/16″ variation. At this stage a careful setup was made, and the frame accurately measured. Necessary correction by cutting, straightening and re-welding was then done. The plan was to use ’38 Ford front suspension. Checking showed that this suspension was short on roll stiffness and it was decided to use the front axle as an anti-roll bar.

This was done by cutting the wishbones and fastening them to the frame that the front engine mounts. To simplify installation of the front suspension the spring hanger was made up and clamped to the spring with its U bolts. Wishbones were attached to the engine mounts and the frame lowered onto the spring hanger.

The hanger was then welded to the frame, in accurate position and with a perfect fit. Later, conventional 40-60 Ford shocks were installed, mounted to the frame with brackets made from 1/8″ sheet steel. With the frame setting on the front suspension, and with the rear of the frame on blocks, the engine and transmission unit was lowered into place. the drive shaft and torque tube were cut and shortened by thee feet.

The radius rods were connected to the torque tube, instead of being spread and mounted to the chassis, as was done on the front end. This was done to eliminate lifting the inside rear wheel on cornering and to prevent excessive tire wear. The U joint was then connected up, the rear spring hanger clamped to the new spring, the rear end of the frame lowered on the spring hanger and welded into position.

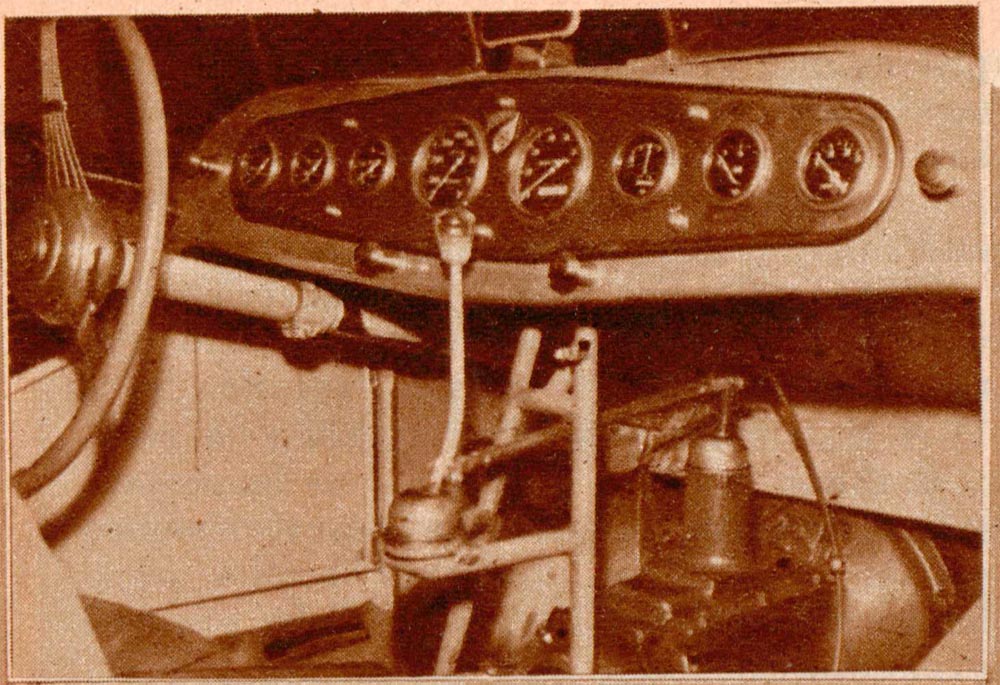

Main difference between American stock steering assemblies and that of sports cars is that stock assemblies are too slow. Sports cars steering, because of the short wheelbase, and frequency of power slides, must act fast. It was planned to use the steering assembly from a Deluxe ’39 Ford, although it would be necessary to reduce the ratios from about 20 to 1, to 11 to 1; or to about two turns from lock to lock.

To do this it was necessary to build a longer Pitman arm. This was done by flame cutting a new arm blank from 1/2′ plate. The spline and taper from the old arm were cut out, fitted into the new blank, and welded together. A pad was welded to the side of the frame to mount the steering box. It was also necessary to lengthen the steering column about two feet, by welding a new section from another Ford steering column.

For this car, the radiator from a ’49 Mercury was chosen, although it was necessary to modify it by installing early model Ford hose connections. The radiator was turned around to reduce upper tank overhang, which interferes with distributor access. Hose connections were then attached.

The gas tank was made from a surplus 20 gallon aluminum propeller de-icer tank. To provide continuous flow of fuel, even tho the car was cornering with low fuel supply, two gas lines were installed. One connection was installed at each end of the tank, and the two gas lines joined together with a tee at the floor level, on the center line of the fuel pump.

The belly pan also serves as the floor of the car. It was made from a sheet of aluminum reinforced by hat sections riveted to the sheet and bolted to the frame. The fire wall was also made from aluminum sheet. A spare tire must be carried to conform with road racing rules.

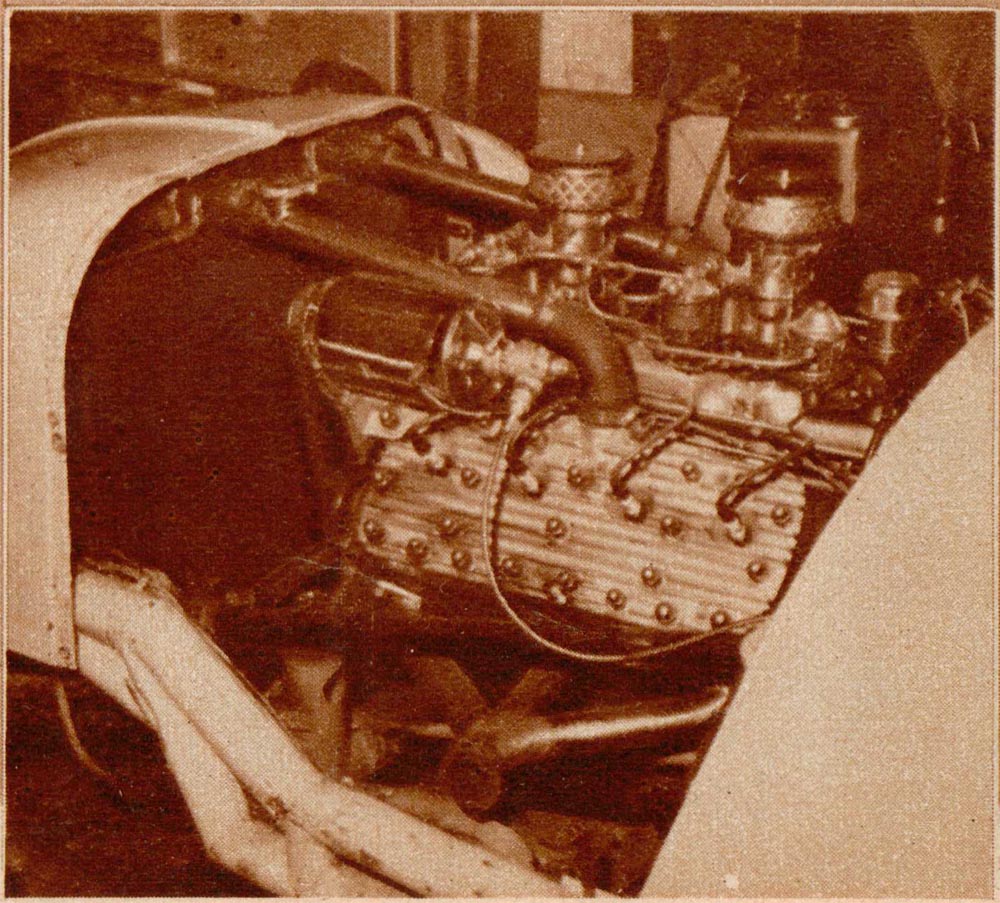

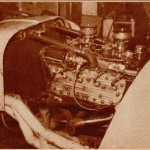

In this case, the spar was mounted vertically behind the driver to act as a roll bar, for protection in case of overturn. In order to provide support for the same reason, a vertical tie was installed in the dash structure, connecting with the cross frame member below. The engine is a Mercury 59A block, bored to 3 5/16″ with 3 3/4″ stroke. Jahns racing piston and Wieand heads and manifold are used. The engine was ported and relieved, and counter bored for mushroom tappets. An Iskenderian mushroom track grind cam, and thirty degree valves were installed.

Carburetors are Ford, Chandler Groves, with the throats bored out 1/8″ and the metering re-drilled to match. Ignition is a 11-A distributor, reworked to use two coils. Braking in road racing is as important as acceleration. Under the heavy demands placed upon them, improper brakes overheat and develop “fade”, caused by unequal expansion of lining and drum. NO production car was found to have brakes adequate for the job.

As heat dissipation is the problem, spot or disc brakes of conventional design are also inadequate. The Alfin Division of Fairchild Aircraft has developed a brake drum that is remarkably efficient in heat dissipation. By a special process, aluminum fins are bonded to cast iron or steel drums, in a manner that transfers heat sufficiently to keep the drums cool.

Another company is soon to market a brake drum, designed by the author, that is more efficient but not so well suited for mass production. At the present time, the body of the Manning Sports Car is of extremely simple construction. The shape is maintained by tubular frames at the fire wall, dash, nose and tail. Flat sheets were used, which were screwed to the frames.

Two hand formed pieces of aluminum were constructed to complete the tail section. The nose is of molded fiberglass construction. It is planned that eventually a complete body, molded from fiber glass, will be substituted for the present body. Independent front and rear suspensions of the swing axle type are also under construction. That the Manning Sports Car has achieved a measure of success in its short existence is evident. Already it has won 1st place at the Palm Springs Road Race and has placed 1st in the Sandburg Hill Climb.

Summary:

Thanks again to Joel Driskill for his help and collaboration in getting this article out to everyone for their appreciation and enjoyment. And be sure to check on Joel’s website from time to time and watch the progress on building his own “Manning Special.”

Click here to visit Joel’s website on building his own “Manning Special”

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————-

Click on the Images Below to View Larger Pictures

——————————————————————-

What can you tell us about the subsequent history of Manning’s car? Also, can you

ID other builders of Cars based on Manning’s plans and what becamee cars?

Hey Joel,

My name is Doug Adler and i have had the pleasure of going down this worm hole…. I have actually built a Manning car from scratch…. Best of all, I had the help of none other than Tom Sparks and Jacque Bellisles who bought the original car from Chuck Manning himself.

Email me for more info at ubugdug@yahoo.com

I also build new style Manning frames which are 3″ mandrel bent!

Tommy and Jacques bought a chassis from Chuck but it wasn’t Chuck’s original chassis. Chuck’s car ran all the way into the early 60’s mostly in it’s original configuration.

Correct, Chuck made more than one car… original car was destroyed racing. He sold the second car to Jacque and Tommy.

I have constructed a couple of them too that Jacque drove before his passing… Tommy was consulted and dared me to

My latest is all mandrel bent with Jack Sutton shaped full aluminum body from Caballo II’s buck…

I have raced them at Laguna Seca, Willow Springs, El Mirage dry lake and Bonneville Salt Flats hitting 136mph.

Oh, and I restored Mosier’s car as displayed at Petersen before he sold it.

Gosh, that’s been almost 20 years now…. So much fun.

I would like to make a correction to a statement I made in this story. The frame was not boxed in, in a chord web chord arrangement. I have acquired pictures that show that they were just non-structural covers that kept rocks and debris out of the car. Sorry about that, I was thinking too much about him being an aircraft engineer.

I would like to make another correction. The way you can tell an early picture of the car is by the fenders. If the rear cycle fenders almost go all the way around it is an early picture. If the rear cycle fenders only go 1/4 of the way around it is the second iteration of the car. Then if it has molded fenders at the rear and wing type on the front then that is the last iteration. So, what I wrote in the intro about which picture was an early on to an older one was 180 to what it was supposed to be. This type of thing happens with research (especially when the researcher is me). I now have pictures of the car during the build and before it got painted that confirm this. Sorry.

Also, one way to tell cars apart is that Jacques Bellesiles’ and Dave Margolian’s used the third iteration Moldings at the rear. Dave’s car used the wing type front fenders while Jacques used flat sheet style cycle fenders at the front. Dave’s car was a wierd sea foam green with a white stripe while Jacques was dark blue with a white stripe.

Joel

the nose looks just like that on the Monsterati, a car that raced in the midwest in the ’60s.

I have read somewhere that the builder of the Monsterati got his inspiration to build his special after reading Chuck Manning’s articles in Road and Track. I don’t know if he used a Manning frame though.

Yes Toly, the Monsterati does look a lot like a Manning Special. The Monsterati is now owned and raced by David Swig (son of Martin Swig). For the last couple of years David very successfully campaigned the car at some big west coast vintage events including the Monterey Historics and Wine Country Classic.

I believe my friend John Streets has one of the Manning Specials much like the one in this article that John still brings out to vintage racing events at tracks like Laguna Seca and Sears Point.

I think that is the one with the yellow nose. There are lots of immages of it on-line.

There tons of good pics if you search – Chuck Manning special – John Streets car was built in 1955 using Manning plans. It was raced for years before being wrecked. It was then restored and vintage raced. Some of the posted immages show great details for refering to when building a tribute copy. It is the one with the yellow noze.

Gene,

Is there a way that you could get John Streets in contact with me. I would like to talk to him about his car. You can PM me on the forum here on forgottenfiberglass and I can give you my personal contact info.

Joel

Hi All:

Interesting story on the Manning Special. I believe there might have been a bit of Canadian content as I think but am not sure that someone up here who worked for Canadair in Montreal (Think Canadarm) might have built a special using Chuck Manning’s plans. If memory serves me correctly, it was called the Canadair Specialas the builder took so many parts from his place of work, it was financed by Canadair – they didn’t know about this…Chuck by the way was an aviation engineer type and the story of his car can be found in Al Girdler’s American Roadrace Special (Out of print unfortunately) I have a copy. I will go to my files to see if I can come up with something more. Cheers, John Wright

John,

I have Al Girdler’s book and many others that cover the Manning special that we will share here on forgotten fiberglass or on my website that is covering my build of a replica. If you have any books or magazines that cover the Canadair Special please share. I am always interested in more Manning information, about the original or a Manning clone.

Joel

There were lots of Surplus stores in LA that got the Government contract over-run stuff for less than 10 cents on the tax payer’s dollar. One was Washington Hardware in South-Central LA. As Art Center students we visited them often for parts for model projects.

I can’t resist, I just would like to make some extra notes on the picture showing the swing axles. Note that the spring is in front of the rear axle and the four bar linkage at the front and rear. Another interesting thing is how the swing axles are “constructed”, with pivots/ or couples from Ford Flathead transmissions to the torque tube. I read about how some hot rod guys were doing this in HONK Magazine. Neat trick, just not one that I am going to attempt!

Joel, take a look at the tech illustrations for the J2 R Allards. This one of the Manning looks like a quick-change was included.