Hi Gang…

Missing pieces of history….thought lost to time….uncovered by auto archeologists near and far. We live for this “stuff” here at Forgotten Fiberglass – and today’s story is the result of one such adventure – Joel Driskill’s Excellent Adventure

Joel’s hard work and fortitude continues to impress me each and every day. He has taken on the herculean task of tracking down the friends and relatives of Chuck Manning in order to understand the man, his car, and his accomplishments.

Today we’re honored to share a never before published booklet put together by Chuck Manning and uncirculated (or little circulated) since he completed it in the early to mid ‘50s. This book either preceeded the building of his race car or proceeded it – we’re still trying to determine an exact date of publication.

And what makes it even more interesting to me is that Chuck Manning talks about the development of fiberglass bodies in detail within the booklet. His thoughts are right on target for the era, gang. He also talks to the core about why specials would and should be based on Detroit production parts with an emphasis on limiting the number of specialized parts utililized in building a “special.”

Here’s what I heard from Joel concerning this booklet:

Letter From Joel Driskill:

Hello again!

Today’s story is possible thanks to the generosity of Chuck Manning’s nephew John Manning. I got in contact with John recently and he was willing to share his stories and knowledge of the Manning Special with me. He was even generous enough to give me what he had of Chuck’s Personal Memory book which contained today’s story, many pictures, articles and objects that will help in the research and recreation of the Manning Special I’m building

This booklet by Manning seems to be an early attempt at writing an article which I think would have led to the series of articles that he wrote for Road & Track. The body of the writing isn’t of great consequence when compared to what he finally wrote in Road and Track but is filled with great illustrations of what he was thinking when he was designing his car.

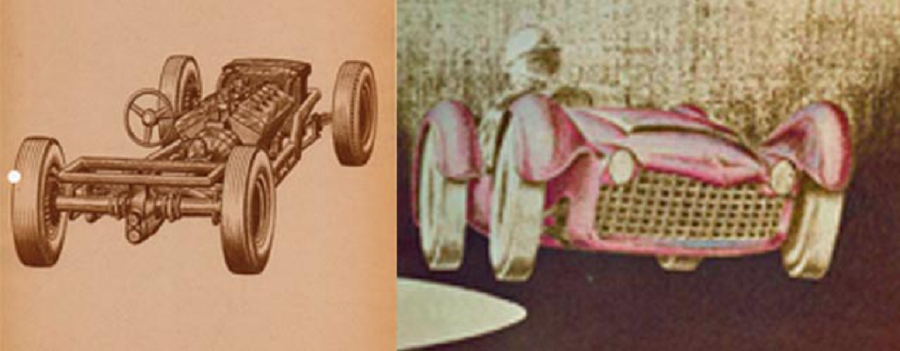

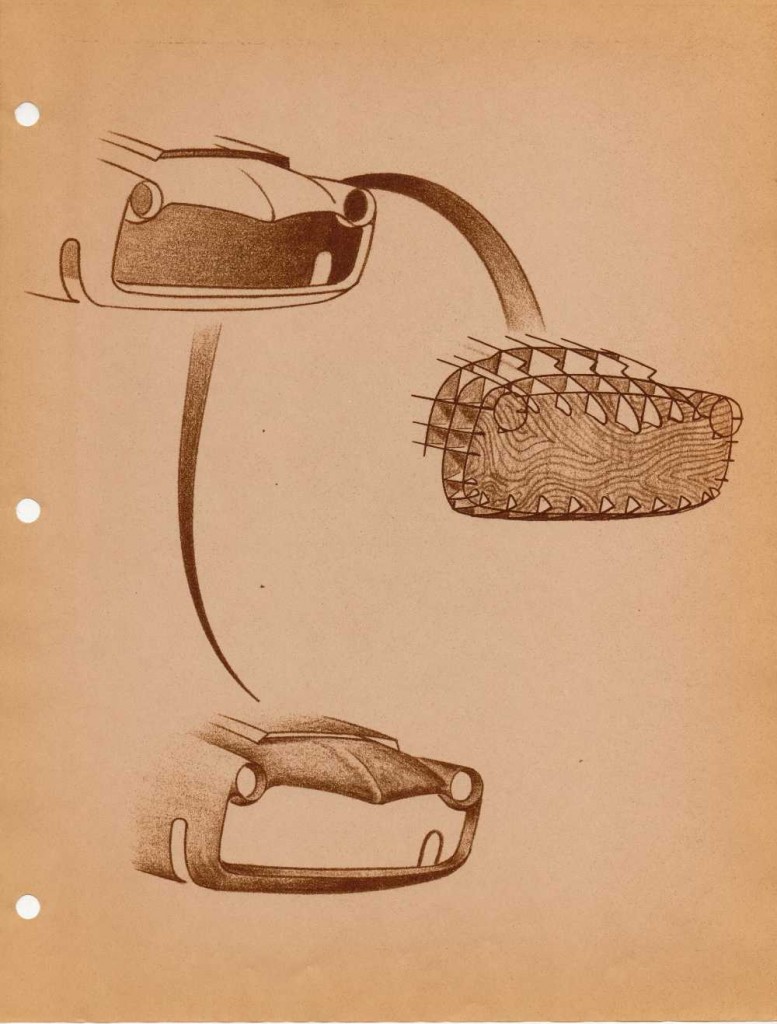

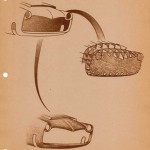

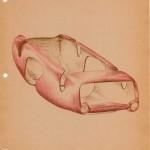

It shows how he wanted the body to be constructed, a single central body with attached winged fenders, and how he wanted to construct his “half swing” axles that he mentioned in other articles that have been posted here on Forgotten Fiberglass. The illustrations also show an example of how the tooling would be constructed

The article does make one statement that would prove to be prophetic

“A company contemplating producing such a car would have to be content with a limited production (not of Detroit magnitude) but would be rewarded by the very limited tooling and facilities required, and by the world-wide recognition their name would achieve.”

He was right – people all over the world recognize the names Glasspar, Victress, Woodill Wildfire, Almquist, LaDawri, Kellison and many others to this very day. These were car companies that were created out of people’s homes and garages with little tooling and the ambition to create a true American sports car.

His own idea would ultimately be right on target as he proved that a well thought out home-built, handcrafted car could compete with the major manufacturers of the day as his car would go on to win races against factory sports cars

Enjoy the booklet (14 pages in total) and illustrations and thanks to John Manning for opening this forgotten page of history to the rest of us.

Manning Competition Car

By Charles “Chuck” Manning

Date: Unknown

Motoring – A Sport

Two hundred thousand see Cunningham team win at Elkhart Lake Grand Prix. Road racing becomes number one spectator sport in U.S. Chrysler, General Motors, Kaiser, Nash, and Ford to show sports models. Headlines like these, taken from national publications, are an indication of the new found interest of the motoring public – sports cars.

This brings up the universal question, what is a sports car? A sports car is a car that is fun to drive. Unlike the Detroit product, which emphasizes its boring simplicity of operation, owning a sports car becomes a hobby of almost unlimited scope. Driving suddenly becomes an exciting experience where each increase in driving skill becomes a source of increased enjoyment.

The next step, by the enthusiast, is the attendance of “Road Races”, to see the men who know how to do it. Now comes the surprising realization – some makes consistently win, while others only “finish”.

Gradually, the sports car owner finds himself mentioning names like Cunningham and Mercedes with a respect almost approaching reverence. These names become a synonym for the very best in design and construction of things mechanical.

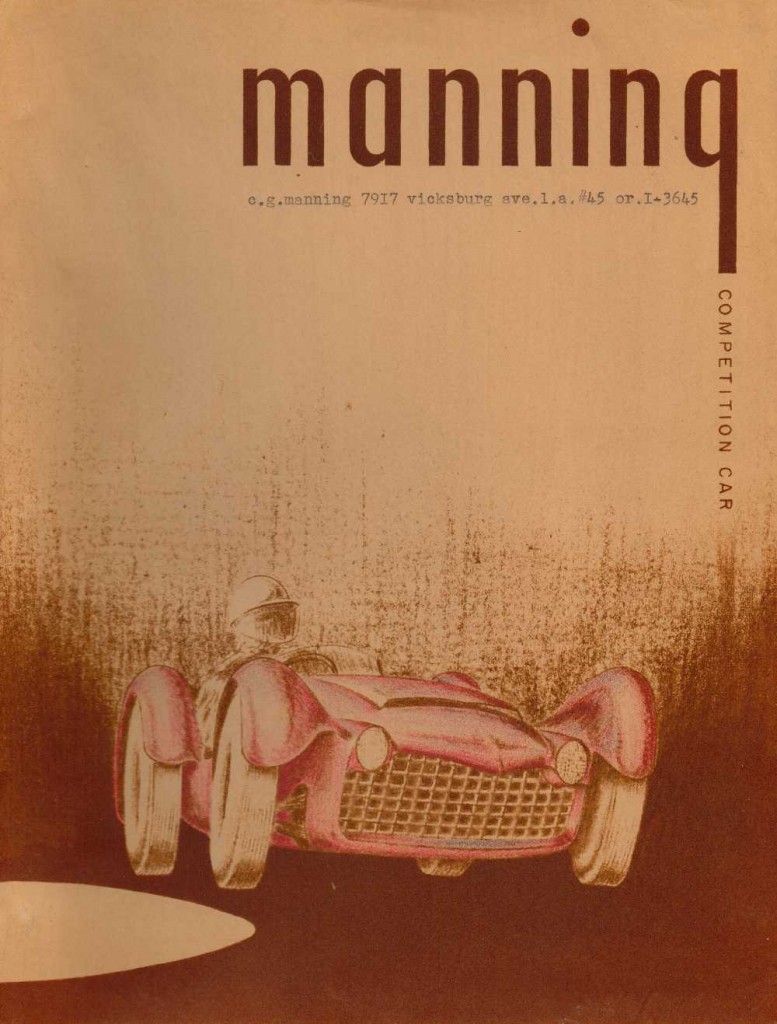

The Body

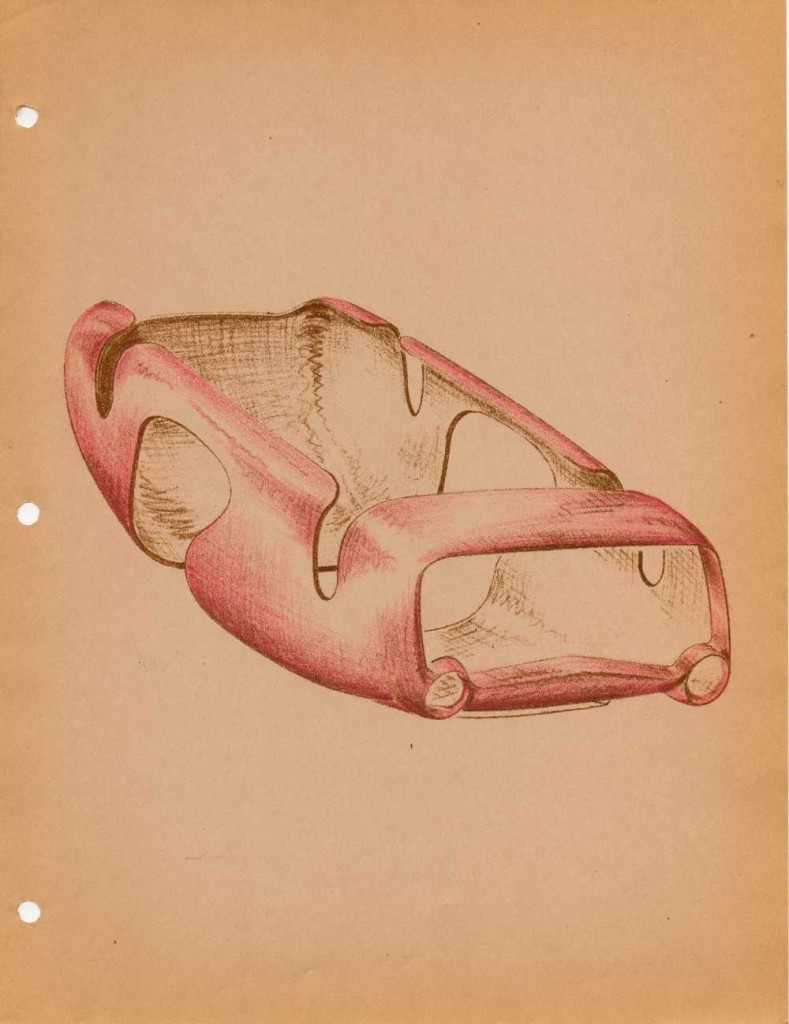

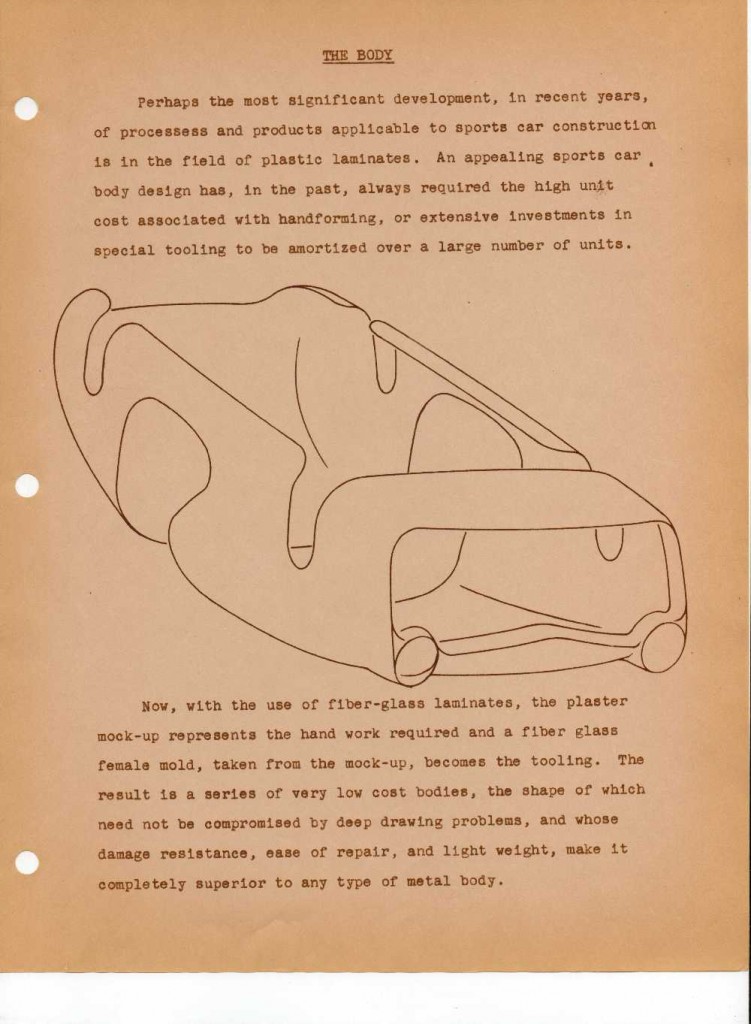

Perhaps the most significant development, in recent years, of processes and products applicable to sports car construction is in the field of plastic laminates. An appealing sports car body design has, in the past, always required the high unit cost associated with hand forming, or extensive investments in special tooling to be amortized over a large number of units.

Now, with the use of fiber-glass laminates, the plaster mock-up represents the hand work required and a fiber glass female mold, taken from the mock-up, becomes the tooling. The result is a series of very low cost bodies, the shape of which need not be compromised by deep drawing problems, and whose damage resistance, ease of repair, and light weight, make it completely superior to any type of metal body.

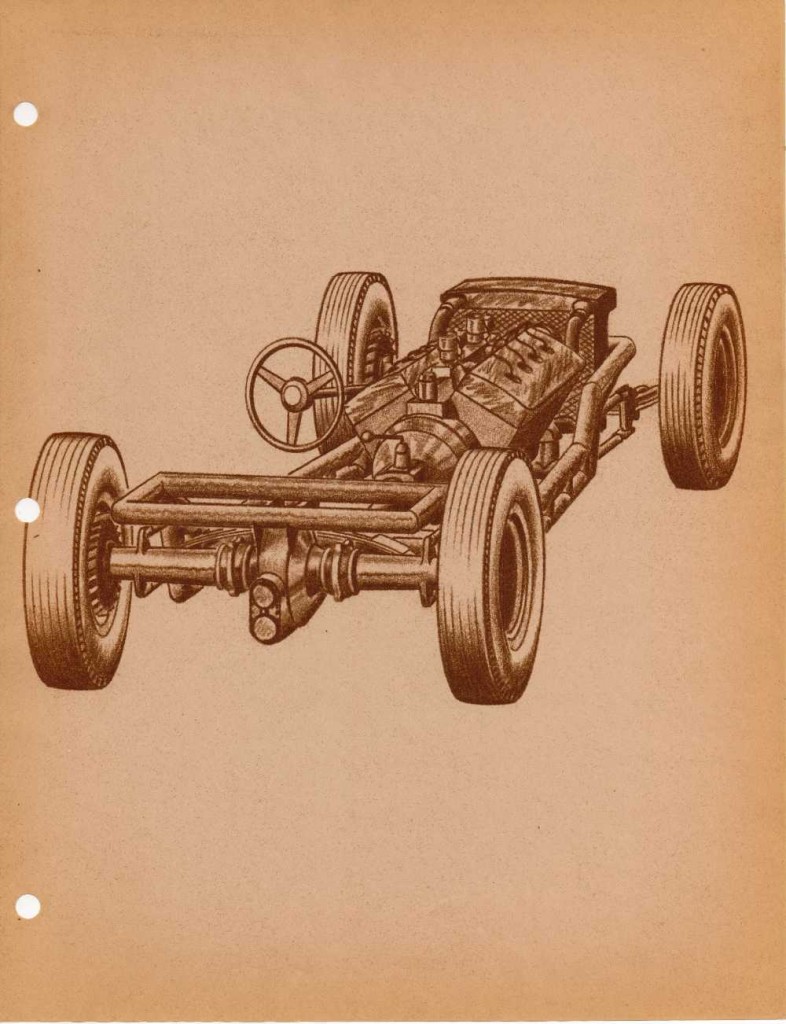

The Chassis

Like all the individual components, the chassis has a few design requirements that cannot be compromised. Simplicity – from a weight, number of working parts, and initial cost standpoint – must be the outstanding feature. There have been a number of designs that have demonstrated this. The English B.R.M. is probably the most highly developed car ever built.

Its performance, on paper, suggests it has no serious competitor. It has yet to win, or even finish a major race. One or more small mechanical failures, of its thousands of working parts, has seen to this. Accessibility – adjustments and replacements of working parts, in a competition machine, are unavoidable. Easy access guarantees this required attention.

Standard replacement parts – One need only talk to a Ferrari owner, who has waited six months for a special metal covered gasket, to hear a vivid description, in four letter words, of the frame of mind poor parts availability induces.

With the number of variety of parts available from the Detroit manufactures, there is seldom sufficient reason to design a component around anything else. The functions of the necessary special parts can, in nearly every case, be limited to features not requiring replacement.

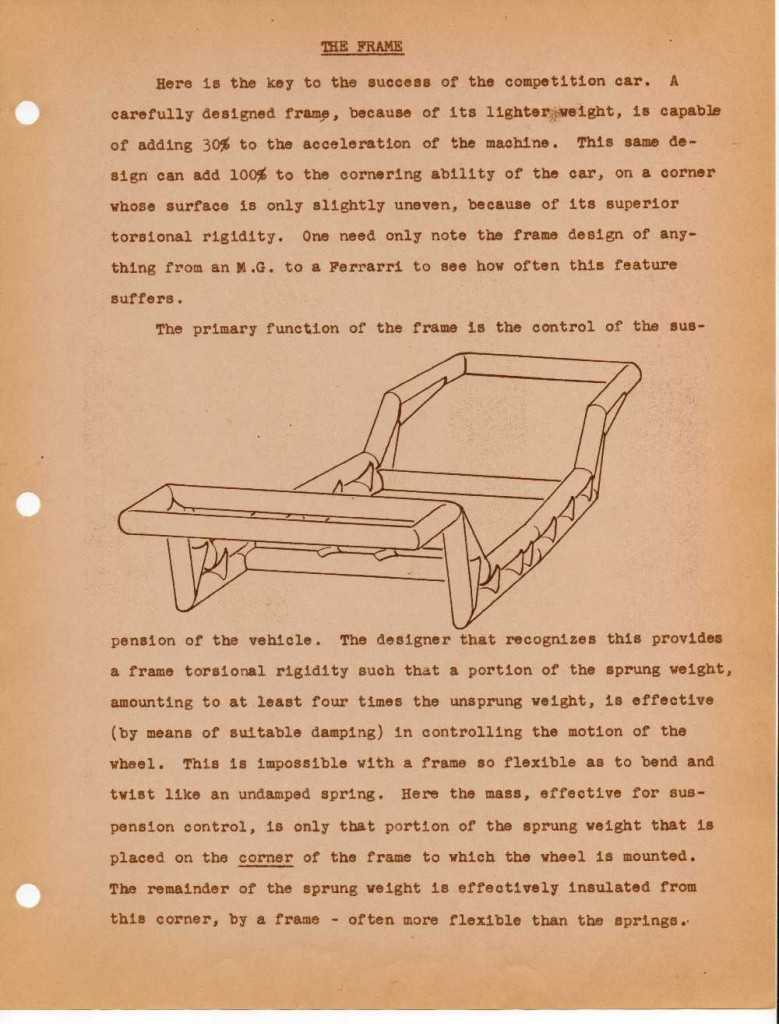

The Frame

Here is the key to the success of the competition car. A carefully designed frame, because of its lighter weight, is capable of adding 30% to the acceleration of the machine. This same design can add 100% to the cornering ability of the car, on a corner whose surface is only slightly uneven, because of its superior torsional rigidity.

One need only note the frame design of anything from and M.G. to a Ferrari to see how often this feature suffers. The primary function of the frame is the control of the suspension of the vehicle. The designer that recognizes this provides a frame torsional rigidity such that a portion of the sprung weight, amounting to at least four times the unsprung weight, is effective (by means of suitable damping) in controlling the motion of the wheel.

This is impossible with a frame so flexible as to bend and twist like an undamped spring. Here the mass, effective for suspension control, is only that portion of the sprung weight that is placed on the corner of the frame to which the wheel is mounted. The remainder of the sprung weight is effectively insulated from this corner, by a frame – often more flexible than the springs.

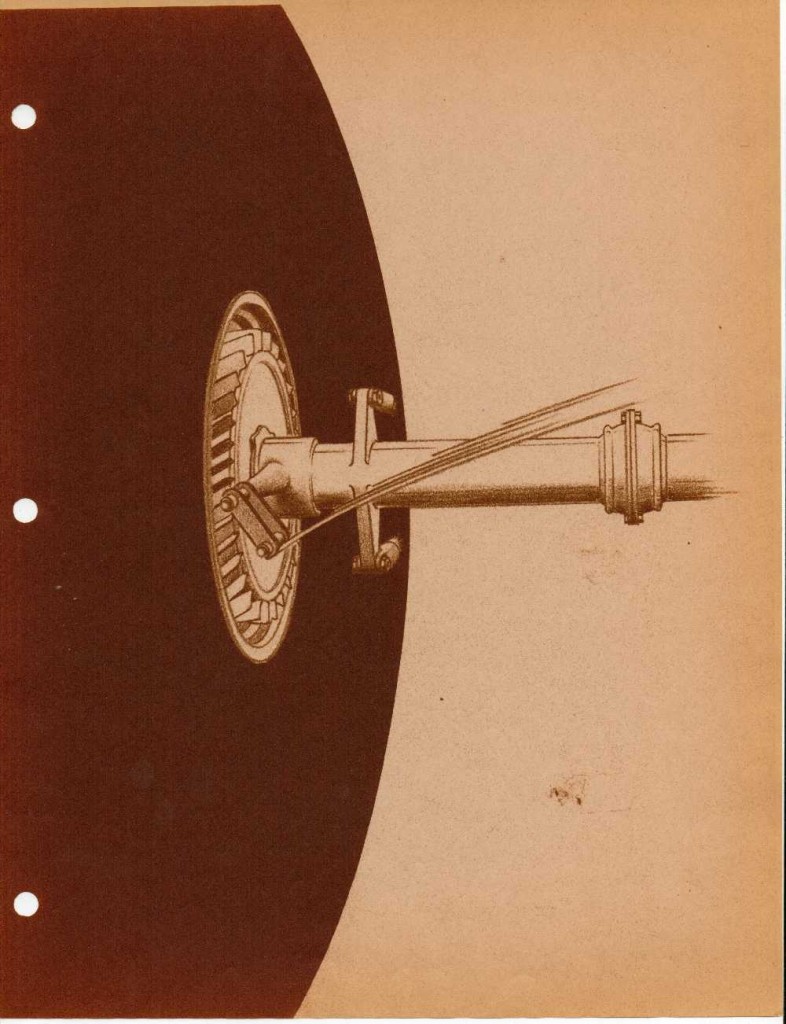

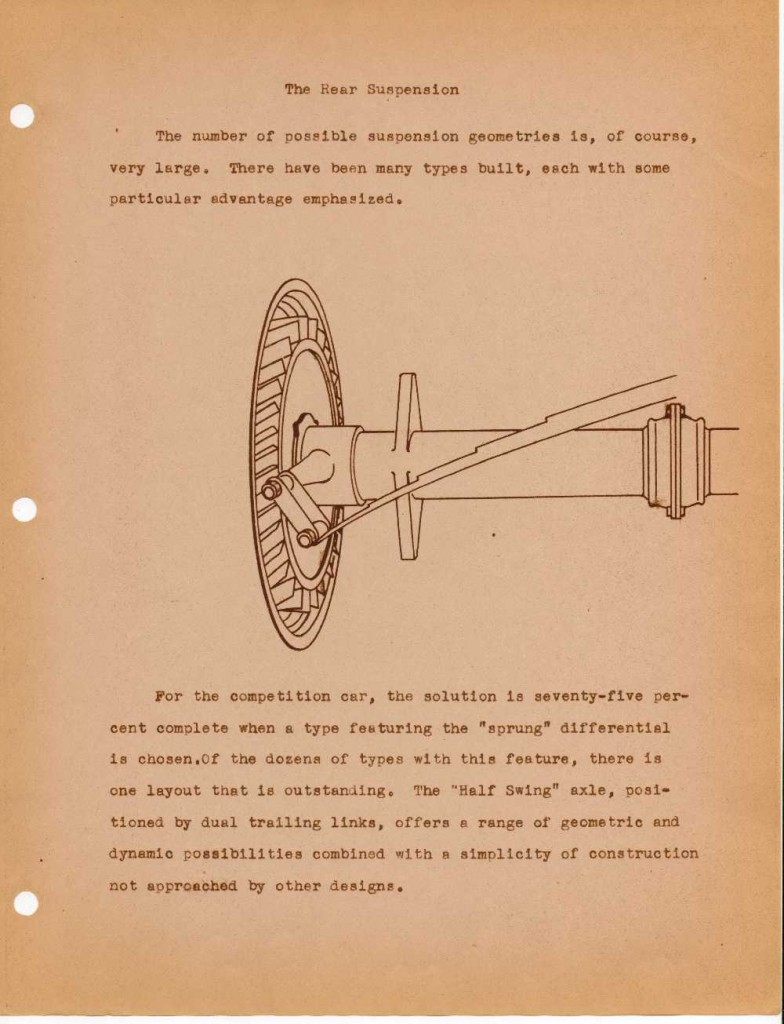

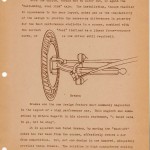

The Rear Suspension

The number of possible suspension geometries is, of course, very large. There have been many types built, each with some particular advantage emphasized. For the competition car, the solution is seventy-five percent complete when a type featuring the “sprung” differential is chosen.

Of the dozens of types with this feature, there is one layout that is outstanding. The “Half Swing” axle, positioned by dual trailing links, offers a range of geometric and dynamic possibilities combined with a simplicity of construction not approached by other designs.

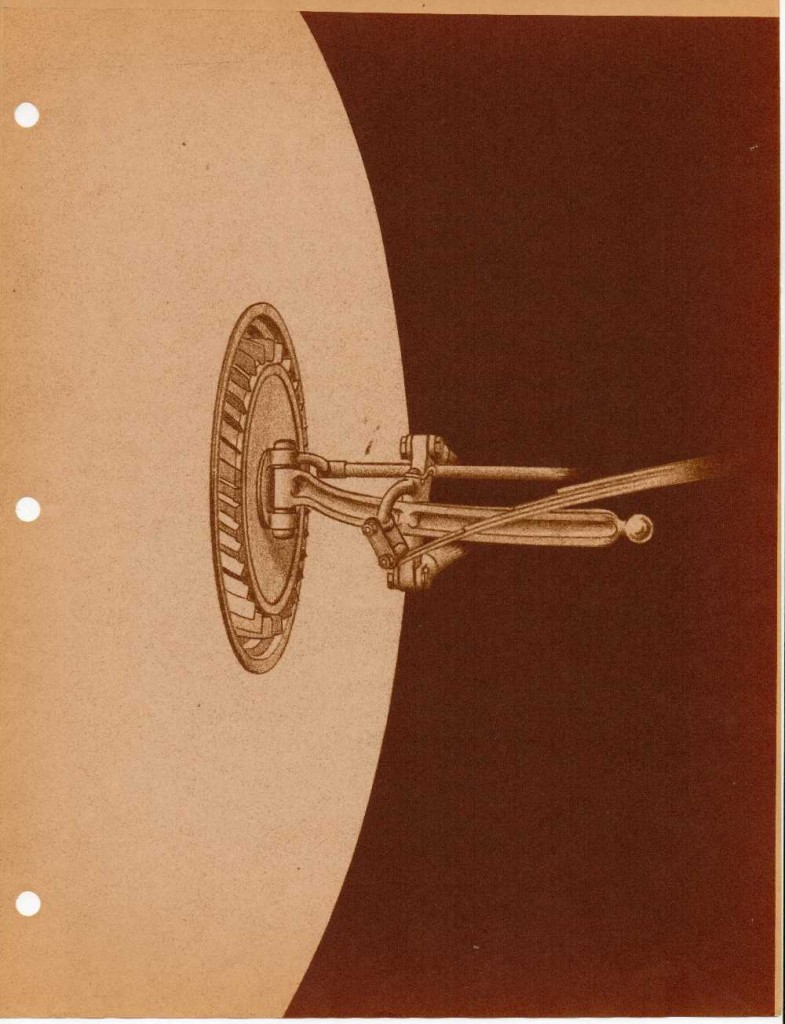

The Front Suspension

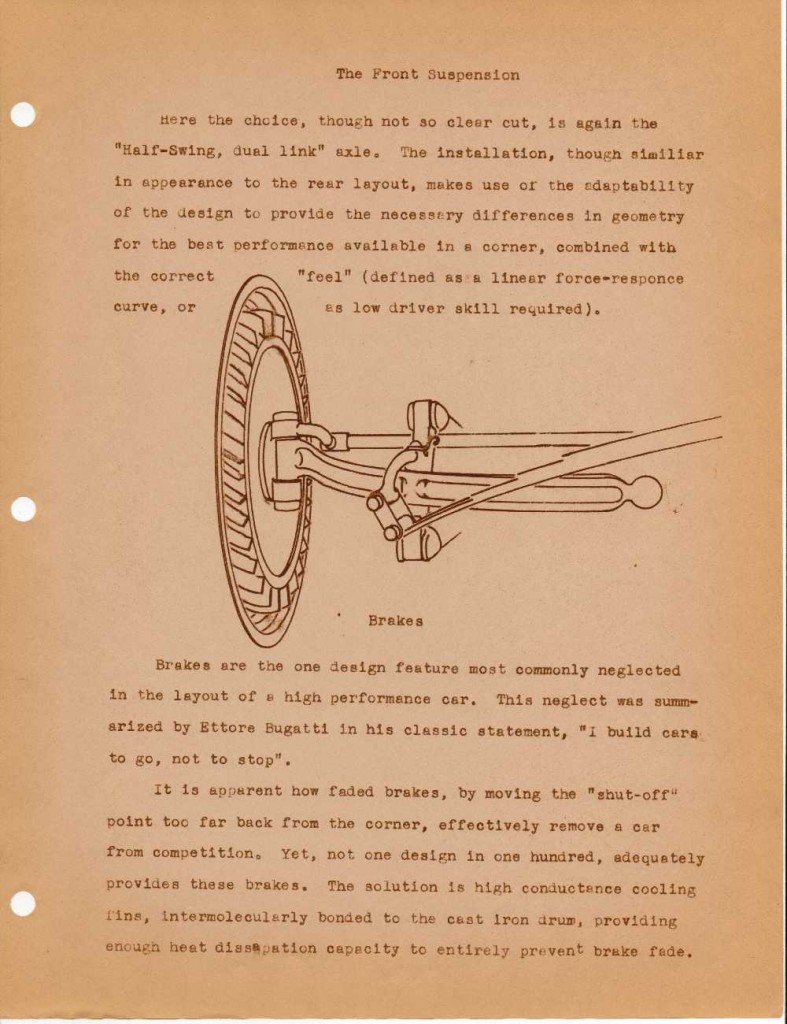

Here the choice, though not so clear cut, is again the “Half Swing, dual link” axle. The installation, though similar in appearance to the rear layout, makes use of the adaptability of the design to provide the necessary differences in geometry for the best performance available in a corner, combined with the correct “feel” (defined as a linear force-response curve, or as low driver skill required).

Brakes

Brakes are the one design feature most commonly neglected in the layout of a high performance car. This neglect was summarized by Ettore Bugatti in his classic statement:

“I build cars to go – not stop”.

It is apparent how faded brakes, by moving the “shut-off” point too far back from the corner, effectively remove a car from competition. Yet, not one design in one hundred, adequately provides theses brakes. The solution is high conductance cooling fins, intermolecular bonded to the cast iron drum, providing enough heat dissipation capacity to entirely prevent brake fade.

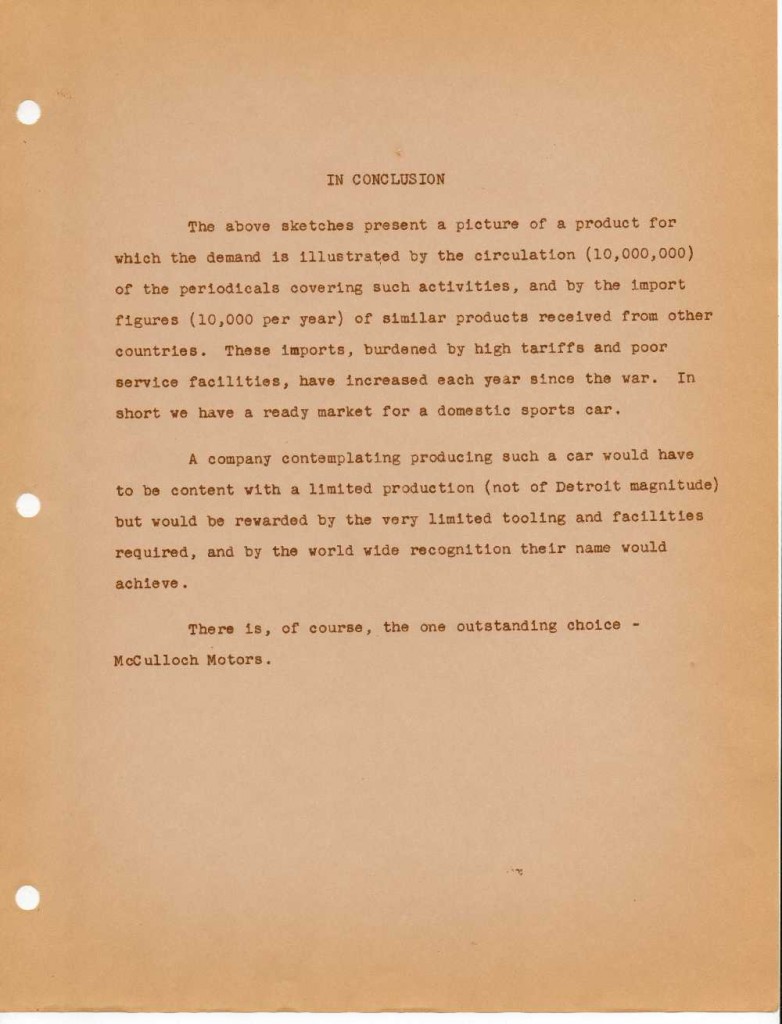

In Conclusion

The above sketches present a picture of a product for which the demand is illustrated by the circulation (10,000,000) of the periodicals covering such activities, and by the import figures (10,000 per year) of similar products received from other countries. These imports, burdened by high tariffs and poor service facilities, have increased each year since the war. In short we have a ready market for a domestic sports car.

A company contemplating producing such a car would have to be content with a limited production (not of Detroit magnitude) but would be rewarded by the very limited tooling and facilities required, and by the world wide recognition their name would achieve.

There is, of course, the one outstanding choice – McCulloch Motors.

Summary:

What a great new piece to share with us and many thanks goes to both Joel Driskill and John Manning for making this happen

So…was this booklet completed before Manning’s Road & Track articles? Was it completed after? And why did Manning end it by identifying his company of choice for production – “McCulloch Motors.” It’s interesting to consider these questions and some of you may be able to answer it if you delve into Chuck Manning’s articles posted here – as a result of Joel Driskill’s work – on Forgotten Fiberglass. Just click on the link below to view all Chuck Manning Sports car stories.

Thanks again to Joel Driskill for his willingness to share this article here for everyone’s review. And be sure to check out Joel’s website and watch his progress on building his own “Chuck Manning Special.”

Click here to visit Joel’s website on building his own “Manning Special”

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————-

Click on the Images Below to View Larger Pictures

——————————————————————-

Extremely interesting. Swing axles could work well in racing and on the road if they were negatively cambered and properly controlled. Not so good on road cars that had to have variability of loading, preventing good camber control. Essential was a limiting loop that kept the wheel from going into positive camber.

At the time this was written McCulloch was very active in planning and building new cars such as the Paxton, intended to be steam-powered. I think this brochure was intended to be seen by McCulloch. John Bond had good contacts with him and could have forwarded Manning’s ideas to McCulloch.

I am one of of Chuck Manning’s old friends. I lived about a mile from Chuck’s home on Vicksburg in LA. I hung out a lot with Chuck in his shop with some regulars: John Bond, Mel Allen, Dave Margolian, Jim Byers, and sometimes Ed Iskenderian. The period was from 1950 until Chuck took a new job with Aerojet General up in Sacramento. I also worked with Chuck at Douglas Aircraft, Elsegundo, but in separate departments. I remember when he introduced me to Ed Heinemann who was Donald Douglas’s chief engineer.

As I recall, he eventually left Aerojet General and returned to LA with the Aerospace Corp. The last time I talked to his wife Norma, she indicated chuck was having some health problems.

I spent a lot of time helping Chuck on his car, and went riding with him to many races. I don,t know how many remember when Chuck won the first Palm Springs road race and received the checkered flag from Clark Gable. The European sportycar guys are still trying to forget.

I never discovered who ended up with Chuck,s original car. However, I am familiar with the Manning cars that Dave Margolian built

Hello Joel I’m working on a 53 Manning looking for info on this vehicle thanks Pat

Hi Pat, would like to see pictures of what you have!

Norb@lastrefugehotrod.com

Thanks

“Im restoring one too!!”

Do you all know what year independent front suspensions first appeared on American production cars? It was in 1934. General Motors engineering design was being run by Maurice Olley and for a number of years prior to the introduction of independent front suspension he ran a research project at Cadillac where they tried to solve wheel shimmy and tramp in the solid front axle equipped cars of the era. One thing they did discover was for improved ride and handling, the front springs needed to be softer than the rear springs. The only way they got rid of wheel shimmy and tramp was to go to an independent front suspension. At first, due to cost, Cadillac was supposed to be the make that got independent front suspension, but Maurice convinced management that all the models including Chevrolet needed to be converted to independent front suspension. Chrysler followed a year later (1935) by copying the GM design. Ford didn’t catch on until the 1950s. Even Studebaker had independent front suspension long before Ford. To continue to use an obsolete design is beyond my understanding

Norbert, Email sent! Looking forward to discussing your car!

Hi, I have one of these survivors, it was raced in the fifties in Canada with a sexy alloy body!. If anyone is interested they can email Norb@lastrefugehotrod.com We can do a story on it as I have history and pictures. There is a missing bit of info. Did the chassis come from Manning or was it built from a drawing? Any help will be appreciated.

Thanks

Just some thoughts on the date of this booklet,

We have hints that it was pre 1955 because it has “road and track” on the second page and not “road & track” they added the ampersand in 1955 . Chuck was not only a contributor to R&T but he was good friends with John Bond (the owner of R&T starting in 1952) and Chuck would have known that they changed the name.

We have another hint that it was pre 1955 because he called the race Elkhart Lake (the city track that was raced from 1950 to 1952) and not Road America (which opened in 1955). We get another hint that it was either 1951 or 1952 by the mention of the 200K that observed the race. The 1952 race had an estimated 100k people that viewed the race on Sunday. I’m guessing he assumed 100k on Sat and 100k on Sun. Also he notes “the Cunningham team win at elkhart lake.” In 1951 a single Cunningham C2R won but in 1952 the Cunninghams took 1st 2nd and 3rd. So, that makes me think he is mentioning the 1952 race.

He also didn’t live at the Vicksburg address after 1954 or 1955 which is on the cover of this story (I have to reconfirm this)

The early design that Chuck had for his frame used 4 inch diameter tubes. He redesigned the frame to use two 2.75 inch tubes for his design later in 1951, due to material availability. So, we know this is post 1951 because of the drawings in the booklet as they have the 2.75 inch tube configuration.

We have a hint it is post 1951 or early 1952 because of the brakes that he drew in the booklet. The car he made in late 1951 had Circumferential fins while he later designed radial finned drums post 1951. Ron Dona, the guy who helped with technical drawings for Chuck’s radially finned brakes didn’t start working with Chuck till 1952. That doesn’t mean that Chuck couldn’t have thought them up before hand and just drawn them in the booklet (the booklet doesn’t have true technical drawings).

With that said I think that it is late 1952 or early 1953. But I’m no historian, I am just a nerd who is trying to do research on this car and happened to find this booklet in the process.

And the comment , “There is, of course, the one outstanding choice – McCulloch Motors”, I think this is just a tongue in cheek comment about the Supercharger company. I think he is just saying, “you could consider all the above statements about frame design and chassis development or you could just spend the money to supercharge your car and to get more horsepower to overcome your shortcomings elsewhere in your car. At least, that’s what the advertisements for the supercharger would lead you to believe…wink” . Again, what do I know.

Just some thoughts

Joel

Another hint would be that HOP UP magazine didn’t exist after 1953 if i remember right.

Great find, Geoff, an extremely important early work. Manning was obvioiusly far more than “just” a stress engineer. And thanks for your comments on suspensions, Erich. Geoff, when Forgotten Fiberglass finally is in print, I think Manning’s booklet could be in the introduction, followed immediately by Guy’s commentary! Thank you. Guy.

Another great find, Geoff. Manning provided a lot of info very concisely. And thanks for the critique on swing axles, Erich

You’re finding some amazing stuff, Geoff!

I I love looking that the illustrations that Manning has in there. I notice the engine chosen in one of the illustrations represents a Chrysler/Dodge/Desoto hemi based engine. Few people today realized that there were hemis before the infamous Elephant (426) motor of the muscle car era… Chrysler introduced the 331 FirePower (Hemi) in 1951 in the Chrysler and Imperial lines. In 1952, they added the 276 FireDome under the Desoto line, and in 1953, Dodge added the 245 Red Ram. They became popular engines for rod, custom, and race, and are still hot today…

I think the illustration represents an Ardun conversion.

I agree Hugh. The fuel pump behind the carbs, distributor up front and the dual upper water hoses suggest Flathead Ford. Also, Chuck was a Flathead guy.

Ted – yes – but I have my hands full with just handbuilt fiberglass sports cars of the 1950s.

Was there much going on in the commercial side of things (fibreglass) like delivery vans, busses etc,?

This really got going in the late 1950s. J.T. Cantrell, the woodie builder was looking into fiberglass commercial bodies in 1958 when they were about to go out of business. Up to that point more commercial body makers used aluminum.

Road America opened in September 1955. As Manning referenced Road America, the publication was written post 9/1955.

Road America was opened in 1955 but they had road races in the “city” of Elkhart Lake starting in 1950.

In 1953 and 1954 the event was held at Janesville WI airport while the current track was being built. Parker Pen Co was there and helped fund the races.

Road & Track was founded in 1947. John Bond purchased it in 1952.

Let me add some context to the Chuck Manning publication.

So, why have fiberglass cars been forgotten, passed over shunned and ridiculed by many who profess an interest in cars?

The evolution of the Forgotten Fiberglass web site, driven by Geoff Hacker, has provided structure to the builders of American post-war sports cars: one, “one off” at a time. The ability to look back over 60 years and gather difficult to find, single pieces of a mosaic, and start to assemble an important missing picture of American sports car development is tedious, hard , manual labor. Frankly that is why it has not been done before: adequately anyway. The early fiberglass bodied American Sports cars have caught the attention of key influencers in the automotive milieu. Established automotive historians, designers and design school faculty, top concour show promoters “get it”. They get the focus of Forgotten Fiberglass’ contribution to automotive history at large. Early American sports cars that practically no one has heard of are getting “hot”.

However, the vast majority of car enthusiasts have probably given no thought, or at best minimal thought, to the origins of the American sportscar. When it comes to the fiberglass segment, fiberglass cars are kit cars, right? Badly made, right? Goofy, right? To move the needle on the guy at the center of American car culture will be very hard and take many years. The Forgotten Fiberglass web site is built on facts. Facts are the only secure way to change the needles set point. The blog capabilities following a posting allow all to input in real time. Thoughtful input can be captured immediately. If a book had been written on this subject, input may influence the second edition, published maybe ten or twenty years later. The forgotten fiberglass web site is the way historical research has to be done now. Nearly all other options are far less productive.

So what about the Chuck Manning publication? Well, as difficult as it is to build the mosaic described above, when you are living in the era of interest it is much harder. It will be much easier to determine the cause and consequences of the global financial crisis, circa first decade of the 21st century, sixty years from now. Chuck did a good job describing the basics of building a sportscar in his publication. But he also spoke to several critical variables that we are today looking to define more accutely.

First, he acknowledged demand. Demand for affordable American sports cars. Second, he provides the logic of using a composite body in sportscar and race car building. Composite bodies still dominate small production race and sportscar building today. Composite materials are relatively cheap, easy to shape and easy to repair. (Composites are so logical for small production cars: it should not be viewed as a low quality option but the option, in my opinion.) Third, he realistically says if you’re going to cost effectively build a small production car you have to use readily available chassis and components, from major car manufacturers. Manning goes on to discuss concepts of frame construction, front and rear suspension and brakes. This introduces a forth important issue: building constructs. He talks about constructs because he recognized that builders were not building kits. His in-period writing is to sports and race car builders who figured out..well, everything. Developed kits were still 5-10 years away.

The Manning publication is an important insight to summarizing what was actually happening in the 1950’s. Now sixty years later we are piecing together the context with the advantage of hindsight.

~

~ @ Guy Durkin, yeah, right, i was just about to say that. (i kid)

the logic and perspective of your remarks, Guy, give a real shape to what all of you are doing in what has to be an historic effort. we are reading, in many cases, experiences of the the prime movers, first-hand accounts of the events by the people that made the industry what it has become. your post states what we are seeing as concisely as it can be said. it is quite exciting for me to witness the doors of time swing away, and learn the reasons behind the mysteries. it doesn’t get any better. i consider myself fortunate to have a bleacher seat for the greatest story finally now unfolding. but more than that, understanding how and why elevates my appreciation. for that, thanks to you all. ~sc

It’s so funny that there was a time when race car builders actually considered the swing axle to be a good design. Ak Miller wrote in various publications about the superiority of the Allard-Bellamy split Ford swing axle suspension and called it the “state of the art”. Today, however, it’s generally understood that the swing axle is an abominable design, one that leads to jacking effect and sudden catastrophic loss of road holding. Think of the Corvair, The Triumph Herald, and early Volkswagens, all of them known for horrific sudden spin outs when subjected to high lateral forces. I hope no one tries to copy this design.

At the time this was it. Allards were the cream of the crop winning all kinds of top races with this set up. You know how racing goes..copy those who are winning. The majority of the articles (for public consumption) about suspension design in the early 50’s state that they hadn’t fully grasped the potential of suspension design yet (just read the early “sports car design” sections from Road and Track). I also think parts availability and cost may have been a problem, at least to the “special” builder, only the most expensive cars had a set up that we would consider good today. I mean, he is trying to build a rear suspension swing axle with drive shaft torque tube couples, that’s pretty far out there. Either way it wasn’t but a couple years later when everyone that was winning was using a fully independent suspension system and we (the general public) saw the light. Although I have read about relatively recent attempts to make Le Mans prototype cars with solid front axles.

In the end Cunningham went back to a straight axel [circa 1954] It should also be noted that Ak Miller was well known for doing things ‘low cost’. He used 1949 to 1952 Chevy car front ends for his Devin specials. This front end assembly was basically the same as 53 to 57 Corvettes used and could be bought for about 10 bucks in the late 50s from junk yards.

The 3000 Austin Healey front ends look like close copies of the ones in 1940 Buick model 40s. When combined with light bodies and quick steering arms, most anything built early post war parts handled fairly well.

Frank Kurtis had much different things to say about the Allard front end when he started building sports cars. This swing axel was actually designed for off the road ‘trials’ racing. It was not for high speeds but rather to keep all 4 wheels on the ground in the mud. The rear swing axel goes back to prewar 170 Mercedes. They were not fast cars. The VW rear ends were generally de-cambered by re-setting the torsion bar splines for racing bugs, formula Vs and dune buggys.

The front axle design was used in the mid 60’s by Ford on their f100 trucks known as the twin I beam, if I remember right they has a commerical showing the truck driving over railroad tracks with a glass of champagne on the hood, and not spilling it !

Gee! What else are you guys going to uncover? You sure weren’t just sitting around whittlin’ in the fifties.

Nope, I wasn’t whittln’ in the fifties I’m only 32 years old. It is amazing what we (contributors to this site) and especially Geoff are able to find. It takes hard work to get this stuff but its worth it in the end, especially when others get to enjoy it.