Hi Gang…

The golden age of building your own fiberglass bodied sports car was 1951-1956.

This is what Rick D’Louhy and I call the “First Generation” of fiberglass sports cars because designing and building your own car from scratch was being touted by every magazine in the country. When the direction changed in America in the late 1950’s, it was to building your own car – in most cases – using a body produced by companies such as Devin, LaDawri, Bocar, Kellison, and Victress. Times sure were different, though, in 1953, and you could build your own – or design and build your own. The sky was the limit.

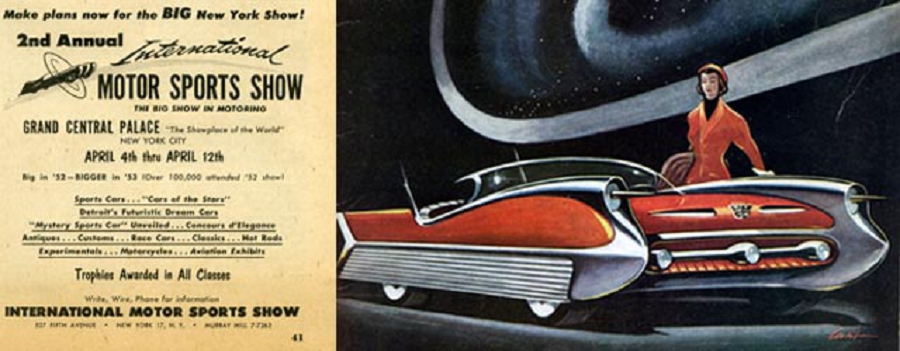

Back then, it seemed like designing and building your own car was happening on every street in American – and auto shows wanted to showcase this explosion of attention too. This was the case with the 2nd Annual International Motor Sports Show held at the Grand Central Palace in New York in 1953.

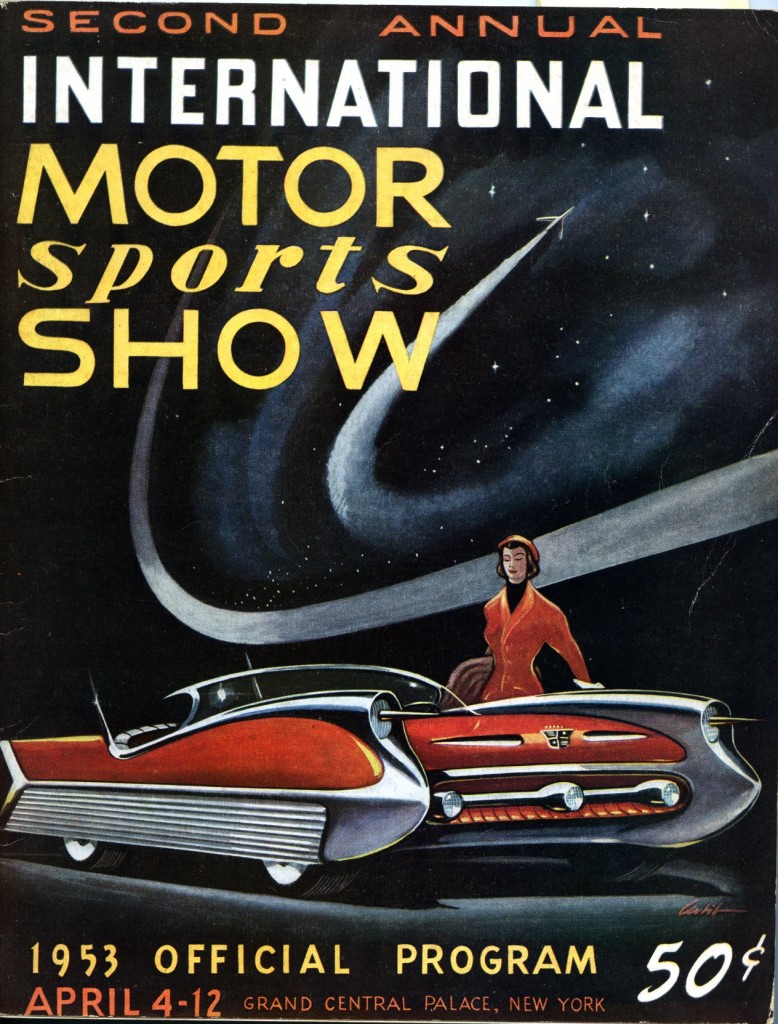

I Love The Cover Of The Program For This Show. This Is A Richard Arbib Design – For You Style Afficionados Out There.

Interestingly, the article below highlights several of our favorite fiberglass car makes as follows:

- Glasspar

- Eric Irwin (and his Lancer)

- Viking Craft (Skorpion)

- Atlas/Allied

- Vaughan Singer (Glasspar and/or Perry Fuller sports car)

As for fiberglass cars at the show, we’re still researching but so far we’ve been able to confirm that Vaughan Singer’s car designed by Perry Fuller was there (click here for more detail on the Fuller car) as well as a Kaiser Darrin. Research continues to identify other fiberglass sports cars that may have appeared there too.

So…it’s with great interest that I share with you the article below. It captures the moment of the era perfectly in the hope and promise of building your own car. As you’ll read below, they stated this perfectly for the time:

“Dreams of super cars which they have nurtured many years have suddenly come within the realm of reality. Automobiles which have never advanced beyond the planning and dreaming stage may now actually be within reach for these thousands of individualists.”

I couldn’t have said it better myself.

And now, for the article.

1953 International Motor Sports Show: Official Program

All Over The Nation, Everyone Is Watching The Progress Of The…

“Boy Wonders And Their Magic Word”

By Max H. Adams, Jr.

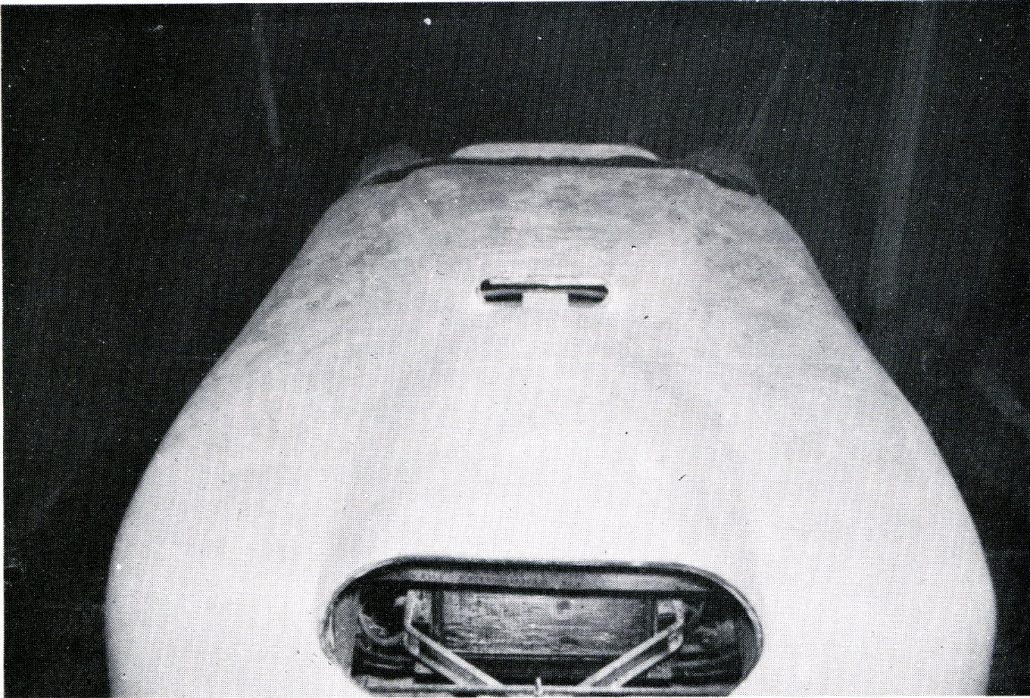

Here’s Another Mystery Car For You – Probably Being Built In The Northeast Given The Location of the Show. Any Ideas On This Gang?

“Fiberglass” has turned into a word more magical than “abracadabra.”

Within the past few months, many self styled automobile designers have received a great new lease on life. Dreams of super cars which they have nurtured many years have suddenly come within the realm of reality. Automobiles which have never advanced beyond the planning and dreaming stage may now actually be within reach for these thousands of individualists.

Formerly the enthusiast who had a few ideas of his own regarding automotive design came up against a tough situation when he advanced to the actual building of his dream car. Not only is custom metal work expensive, but skilled technicians of the caliber required to execute designs in three dimensions of steel or aluminum, are scarce indeed.

Even the most optimistic home grown designers are usually loathe to attempt their own metal work. Now this new medium…which still requires plenty of skill….tempts every novice body builder into trying it on his own.

Once a full-size plaster mock-up is finished, the next step can be handled by the “boy wonder” himself. By merely reading the directions and applying layers of fiberglass cloth, properly coated with resin, almost anyone can turn out a reasonable facsimile of a Detroit body job, in his own back yard. Sun curing completes the process and the work is ready for final sanding and painting.

The final results are, of course, in direct proportion to the amount of effort and talent expended, but in any event, the body can be built easily and inexpensively. The actual expenditure for plastic material will hover around $400 for a full size car.

This new boom in the medium of the future has brought forth many companies to make these materials available to the public. $10 will bring you a complete kit with which you can try out your hand at fiberglass moulding. Glasspar, Eric Irwin, Viking Craft, and Atlas have become familiar names among the motor fraternity.

A sprinkling of semi-production bodies by Skorpion, Vaughan Singer, and others have been seen throughout the country during the past year. Many of the special-built “Lakesters” at Bonneville Salt Flats last August were of plastic construction, using its extreme lightness for increased speed.

Hard tops for convertible models by several firms are just one more growing item made from this chemical process…lighter than aluminum and almost as strong as steel.

Just how far this material will go in the automotive field is difficult to judge at this point. However, recognition by the leading manufacturers of the nation is a fact and several firms who have produced plastic, advanced design models. At least two auto plants actually have plastic models in production.

In any event, the progress of plastic will certainly be watched with intense interest by all in the motoring field, whether they be hobbyists, dealers, or just Mr. Motoring Public.

Summary:

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————–

Click on the Images Below to View Larger Pictures

——————————————————————-

- I Love The Cover Of The Program For This Show. This Is A Richard Arbib Design – For You Style Afficionados Out There.

- Here’s Another Mystery Car For You Gang – Probably Being Built In The Northeast Given The Location of the Show. Any Ideas On This Gang?

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.