Hi Gang…

The earliest known replica of a Cord that I’m aware of was done by – who else – the legendary Glenn Pray of Tulsa, Oklahoma. Here’s a bit more about the man and his story from the website http://www.glennpray.com/:

“Glenn Pray. Who is Glenn Pray? (From http://www.glennpray.com/):

What had he (Glenn Pray) accomplished by the summer of 1963 that made him famous enough to be considered a who’s who in America and a contestant on this very popular game show? What was his claim to fame? Who was he then and who is he now? The world would later learn that this young entrepreneur with sheer determination and a borrowed 20 dollar bill bought the Auburn-Cord-Duesenberg Company and began manufacturing the “second generation” Cord and Auburn automobiles.

Little did the world know the enormity of his genius. Despite enormous obstacles, he would rise to the top of his profession. He would link up with US. Rubber and create the first therma plastic car ever made in the world. His Cord 8/10’s would be the very first American car designed and produced with front wheel drive after WWII. He would arguably be the first person to design an “office on wheels” …the first mini van.

He would be the first to design, patent and create the Auburn dual cowl phaeton automobile…(a highly collectible model to this day). His company, the Auburn-Cord-Dusenberg company also has the profound distinction of being the oldest car manufacturing company still in business to this date in American history. More over, he would become known throughout the country as the “Will Rogers” and “Mark Twain” of the automobile industry…a much sought after motivational speaker and gifted story teller. Glenn Pray’s audience could not get enough of his plain spoken humor.”

Glenn was quite the man, and I wish I would have been able to meet with him in person. Sadly, he passed away earlier this year (2011), but his legend and what he accomplished continues to be recognized to this day.

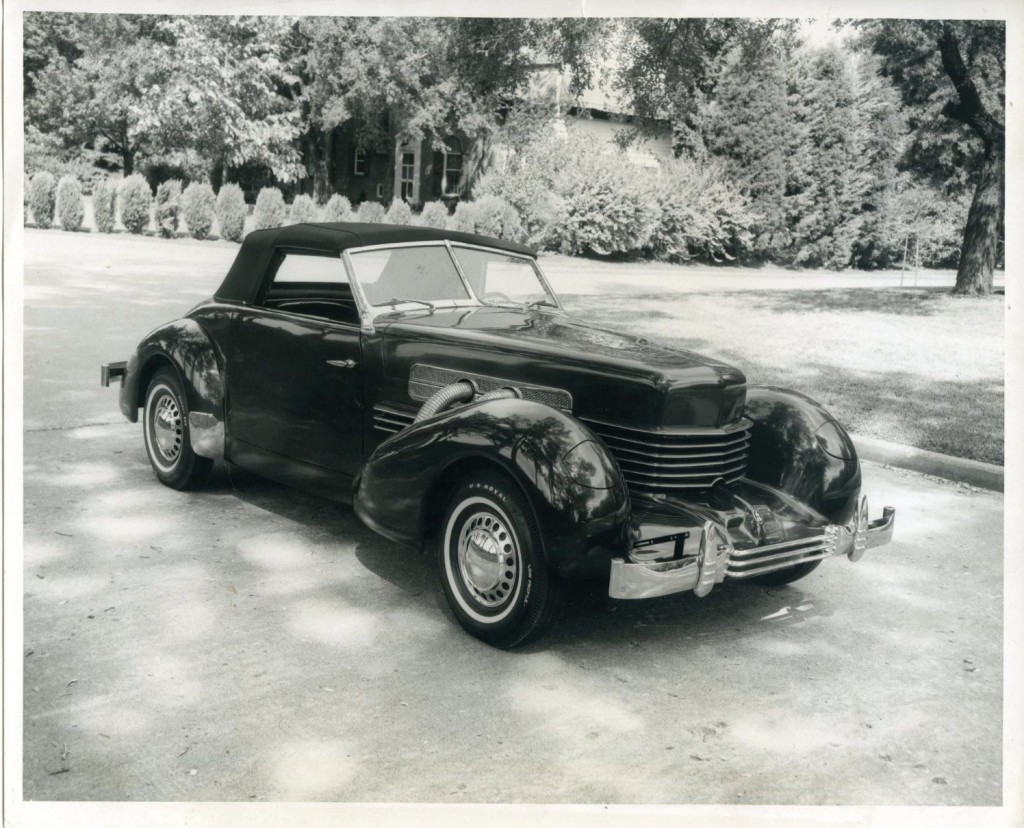

The 1937 Cord – Reintroduced in 1964 in Plastic:

Recently, automotive historian Glenn Brummer alerted me to an ebay auction showing the press release of what I believe is the first “plastic” (not fiberglass) production car built in America, I seized the opportunity, and became the high bidder for this piece of history. Here’s what I learned when the photo and press release arrived:

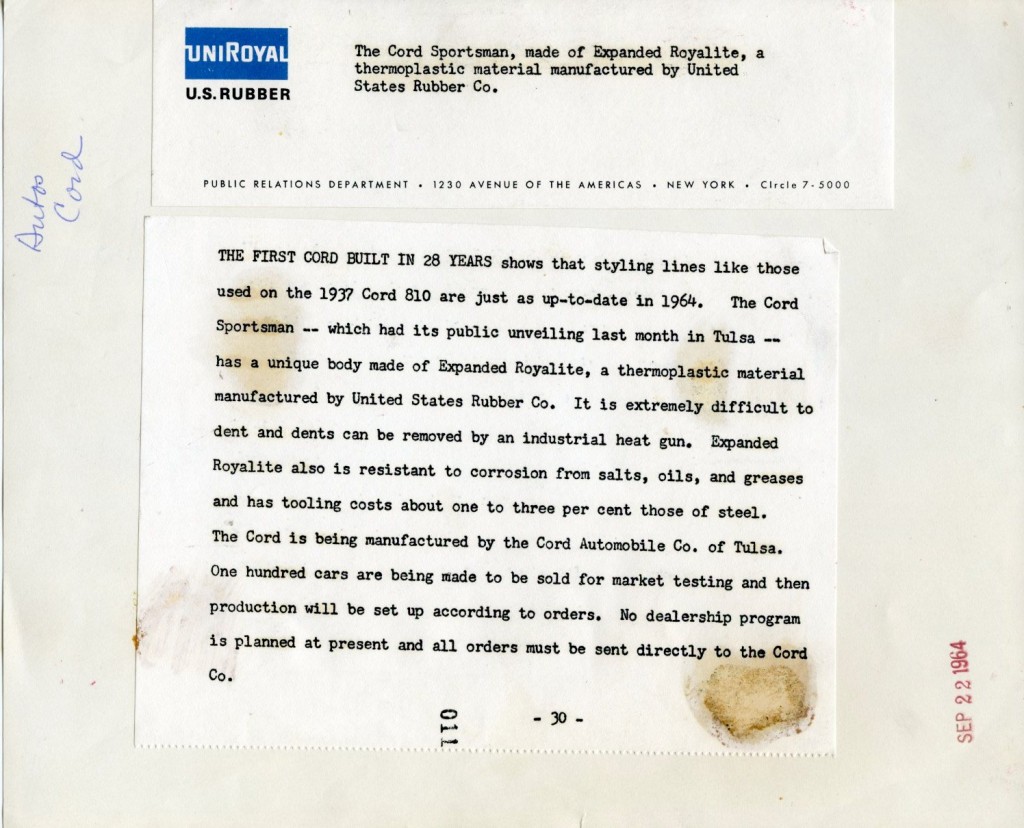

Press Release: September 22nd, 1964

Uniroyal / U.S. Rubber

The Cord Sportsman: Made of Expanded Royalite

A thermoplastic material manufactured by United States Rubber Company

The first Cord built in 28 years shows that styling lines like those used on the 1937 Cord 810 are just as up-to-date in 1964. The Cord Sportsman – which had its public unveiling last month in Tulsa – has a unique body made of Expanded Royalite, a thermoplastic material manufactured by United States Rubber Company.

It is extremely difficult to dent and dents can be removed by an industrial heat gun. Expanded Royalite also is resistant to corrosion from salts, oils, and greases and has tooling costs about one to three percent those of steel.

The Cord is being manufactured by the Cord Automobile Company of Tulsa. One hundred cars are being made to be sold for market testing and then production will be set up according to orders. No dealership program is planned at present and all orders must be sent directly to the Cord Company.

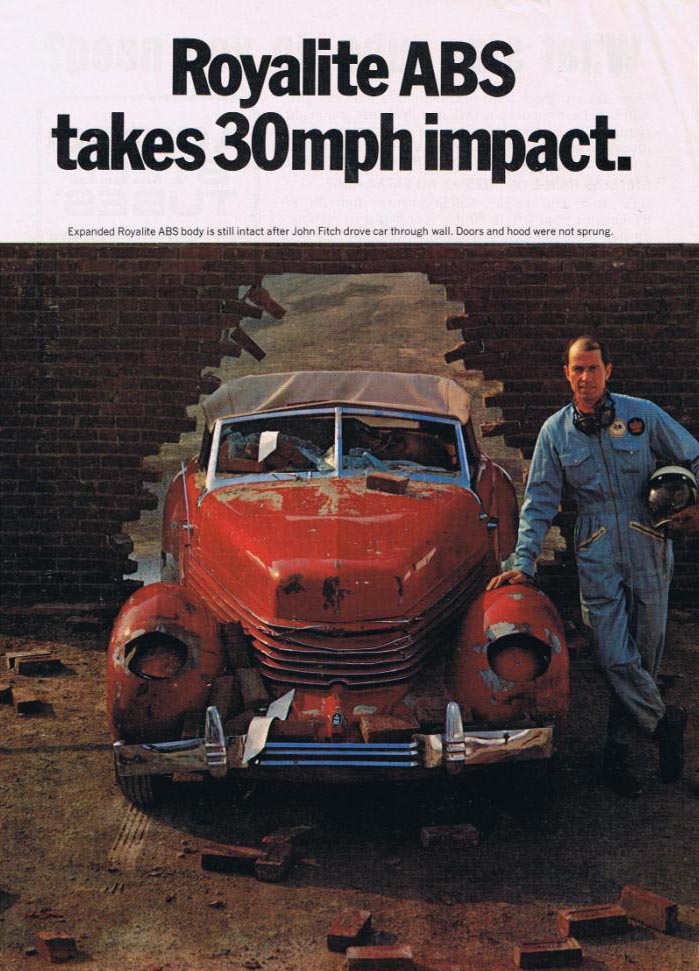

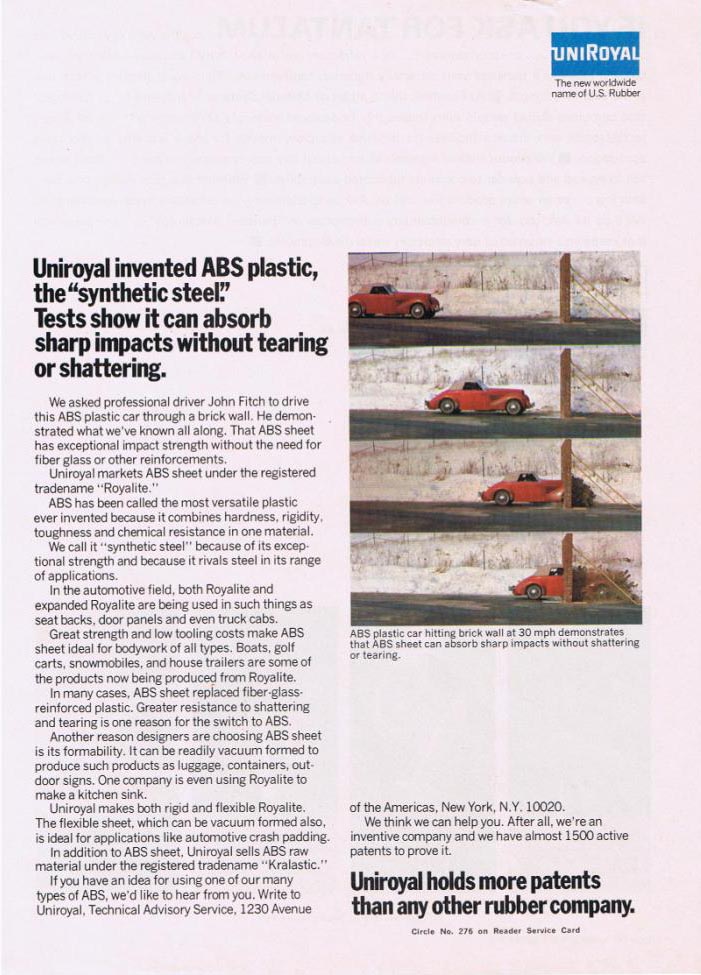

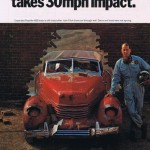

UniRoyal (US Rubber) Demos ABS Plastic – In A “Smashing” Way:

I poked around a bit more on the internet and found an interesting advertisement using Glenn Pray’s Cord showing the strength of the product. It reminded me of Henry Ford pounding the 1939 fiberglass trunk lid with an ax, and other fiberglass luminaries of the 1950’s demonstrating the rigidity and the ease of repair of fiberglass. The two-sided ad is shown below. And yes…..that’s a plastic Cord going thru a brick wall. That’s too cool. There’s lots of brick walls near where I live…. I think I could benefit from having one of these cars out at Fiberglass Farms (watch out Rick!)

Plastic Fantastic: And a One, And a Two….

While fiberglass sports cars continued to be released in the 1960’s, at least one more “plastic” car appeared too – the CRV / Piranha. The initial runs of these cars were produced using a plastic material trademarked as “Cycolac.” We’ll discuss these cars in detail in the future, but in the meantime, those of you who are at the edge of their seat wanting more info should visit the best website showcasing information about these cars written by historian Nick Whitlow. Click here to visit the CRV / Piranha website.

Summary:

I look forward to learning more about the Glenn Pray “plastic” Cord from experts out there. Perhaps we can convince them to write a story – or two or three – for our Forgotten Fiberglass audience. Glenn, his vision, and his cars are quite a story, and friends of fiberglass like Arthur Maimbourg out there in Oklahoma who knew Glenn would appreciate reviewing and contributing too.

To support this recognition of Glenn’s accomplishments on our website, I’ve created a “Glenn Pray” category of stories – the first of which you are reading today. I look forward to expanding the cadre of stories about Glenn in the near future. And be sure to checkout http://www.glennpray.com/ for some great history and background on the man and his cars.

Hope you enjoyed the story, and until next time…

Glass on gang…

Geoff

——————————————————————-

Click on the Images Below to View Larger Pictures

——————————————————————-

Greetings.

I have serial #1, that Glenn gave to Gordon Buehrig, and was acquired by my Grandad, Fred Bauer, in the 70’s. Granddad had #3, and my uncle still has it. Neither are currently running.

I have an article that he wrote for Cars and Parts in 73 that detailed the history, and his involvement as an investor in the company. I need a forum to get that story out to the Cord community.

Hi, I am in the UK and have a Glenn Pray #10 which I believe is the only one here. Currently restoring it and only a few little jobs to do. Can anyone tell me what heater was standard if any. Mine has a petrol South heater plus a monster Aitcon unit. I would like to remove the Aircon as it doesnt seem original and doesnt work. Dont want to deviate too far from original but dont need heating or aircon in a classic.

Rob, I sincerely hope you do have #10 as I owned for a number of years after buying and bringing it from Arizona to Oahu, Hawaii after it had sat for many years. I had it for more than 5 years before selling to an older gentleman that lived on Maui. As he was restoring, he’d send me updates, then one day they just stopped, his business had new ownership, and I got no replies from him. I tried to find out what happened to both him and #10…but nothing. I was worried it was abandoned somewhere on Maui and would eventually be lost to the elements. So, I do hope it made to the UK. When I had it, the original Aircon compressor was in the trunk, all the rest was still mounted as originally installed, and the heater wasn’t there. The original parts man at the factory, Felix was still working and documenting the history at the factory in Oklahoma a few years ago.

What is the rest of the story? Is the car Rob has #10?? Did the Aircon system get removed? When was the Aircon system installed? If it is #10, how did it get to the UK?? So many questions! So many cliff-hangers!

I am glad someone still remembers these cars. My father designed and fabrication. He also did the interier upholstery. Brings back memories.

Lee Church, son of Peter J. Church

Great article, enjoyed the glimpse into postwar ingenuity and the re-emergence of the American spirit.

Geoff,

In the first part of the article you quote from http://www.glennpray.com,

“Little did the world know the enormity of his genius. Despite enormous obstacles, he would rise to the top of his profession. He would link up with US. Rubber and create the first therma plastic car ever made in the world.”

Later in the article you correctly identify Royalite ABS as a thermoplastic. I mention this because it may have been a typo when you typed the quoted information.

One of the earliest plastics was Bakelite, a thermosetting plastic. These were used to mold combs and other vanity articles starting about the 1920’s or perhaps even earlier. Early plastic radios were thermosetting plastic. They took a permanent form when heated, thus the thermoset moniker.

Another early plastic was cellulose nitrate, which was used to make the stiff collars for white shirts popular in the 1920’s. Shirts did not come with collars and they used the plastic collars that retained their shape and could be wiped clean. That way a shirt could be worn with a suit for a number of days and still look pristine because the collar did not wilt.

There was a huge amount of plastics research in the 1930’s when DuPont invented rayon and nylon and cellulose acetate replaced cellulose nitrate, although not for shirt collars because the separate collars went out of style.. Nylon stocking replaced silk stockings (with the seam up the back) but nylon stockings disappeared early in WW2 when the bulk off the nylon was used for parachutes and other military applications.

Cellulose nitrate was very flammable. I worked for a company from 1947 (at age 13) to 1953 that sold a small amount of cellulose nitrate sheets. They occupied the top three floors of a four story building in downtown Boston. The cellulose nitrate sheets were stored in a raised shed about 3 feet high and 5 feet square on steel angle iron about 18 inches above the roof of the building. That way if the cellulose nitrate sheets caught on fire it would not burn down the building.

The bulk of the plastic sold was cellulose acetate. The clear cellulose acetate came from the factory in 40 inch wide continuous rolls that weighed close to 200 pounds. Two of us would remove the top cover and lift the hard cardboard tube that contained the roll up onto a bench, and stand the tube upright so the cardboard tube could be lifted off the plastic roll. We then would insert a steel rod into the center of the roll and lift the steel bar onto a frame so we could unroll about 25 feet of 40 inch wide plastic onto the bench. We would then take a cardboard template measuring 20 by 50 inches and with an awl we would scribe a line to guide our cutting the 20” by 50” sheets. To this day I can cut an amazingly straight line with a pair of scissors.

ABS (acrylonitrile butadiene styrene) thermoplastics came on the scene in the early 1950’s. US Royal was one manufacturer and another was Bolta Plastics (owned by John Bolton), who started out injection molding thermosetting plastic years earlier. Their ABS product was called Boltaron. I have some interesting stories about John Bolton, but no time for that now. The ABS sheets were typically about 1/16” or 3/32” thick and could have a pattern embossed on one side. The pattern is similar to what you see today in many plastic panels in an automobile, although most of those are produced by injection of compression molding.

In the early 1950’s a process in wide use was vacuum forming. A mold was made, typically of wood for short runs, and metal for longer runs. The ABS sheets would be heated until soft (like pizza dough before baking) and clamped over the mold so air between the mold and the plastic could be evacuated by vacuum. The molded sheets would be trimmed with a router, holes drilled, etc. The molds for Injection molding were very expensive so vacuum forming was used for shorter runs.

Anyway, I thought you would like to know what ABS stood for.

Ron

Ron,

Loved this post!! Since this is from 2011 I am not sure if you will get this. But, boy do I love to hear me some history form the guys who lived it!

I have Glenn Pray’s #61 Cord. Currently, I am working out the mechanical issues. Eventually, I will need to address bulging of the door panels and distortion of the sides of the engine compartment just under the hood.

wow! glenn pray & john fitch! there’s a pair to draw to!

http://en.wikipedia.org/wiki/John_Fitch_(racing_driver)

his corvairs were favorites during college years. (along w/ yenko stinger)

sc